What was the challenge or problem to solve?

In this project, INFINITIA’s Product Development team had to design and manufacture a support for plastic homologation, to carry out laboratory tests on plastic specimens under controlled humidity and temperature conditions in order to obtain the homologation of this material.

Taking all these constraints and specifications into account, the Product Development team designed a tool that met the customer’s requirements.

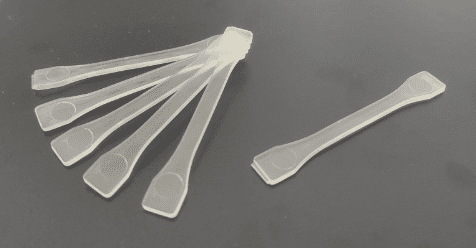

The first step to be taken in this project was to measure the specimens to be used in the homologation tests and the space available for the assembly, using precision metrology tools. Due to the size restriction, this part was very important since the available space had to be optimized. Then, the specimens were digitized to obtain a 3D model of them. Next, the specimen holder was designed taking into account the dimensions of the specimens and the space available in the laboratory.

After finalizing the design of the support, it was validated together with the customer and the drawings of the part were made for its subsequent manufacture by CNC machining. Due to the humidity and temperature conditions that were necessary to perform the test, it was decided to manufacture the tool in stainless steel to have good mechanical properties.

Finally, and once the manufacturing process was finished, the support was delivered to the customer, who was able to verify that the support met all the requirements and limitations set at the beginning of the project.