What was the challenge or problem to solve?

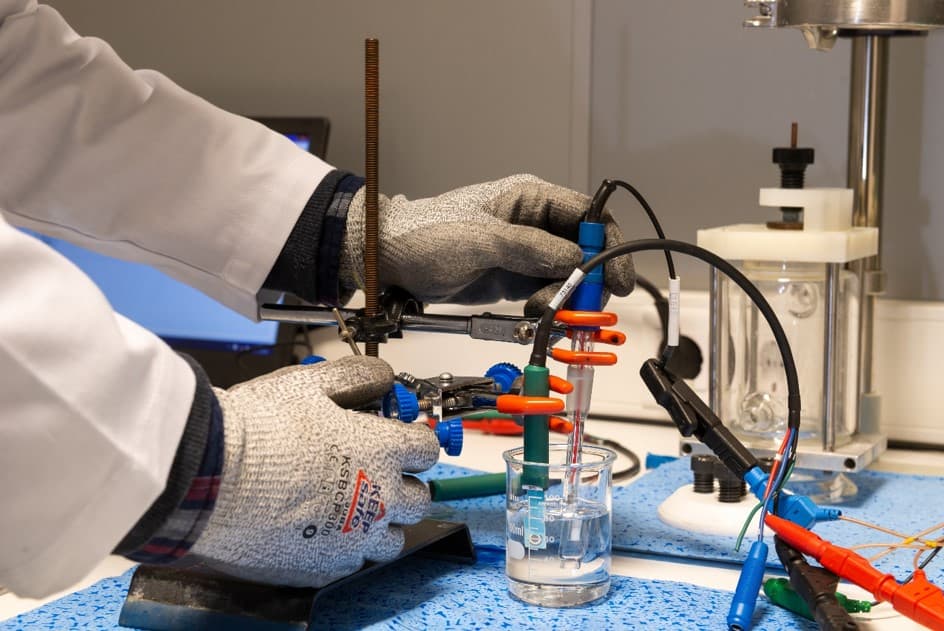

This reactor had high specifications due to the working conditions, such as corrosion resistance, temperature, electrical insulation and good sealing.

How was it addressed or what was the solution?

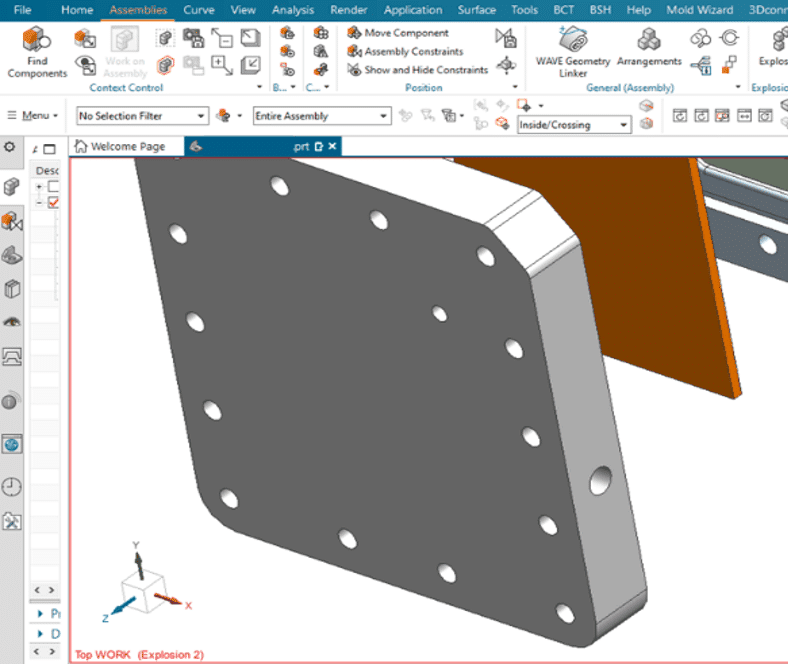

The Prototyping team designed several models of the reactor, which were manufactured by 3D printing, specifically with FMD technology in different materials and percentages of fillers, and with SLA technology.

After fabrication, the different configurations were tested in the laboratory, so that they were optimized and iterated until a final design was reached.

Once its operation was verified, the final reactor was manufactured in the selected material by machining.

Challenge

- Design and fabrication of a prototype reactor according to specifications

Solution

- Manufacturing by 3D printing

- Design validation and laboratory testing

- Design iteration

- Manufacturing of the final design by machining