What was the challenge or problem to solve?

The use of collaborative robots in production lines is an increasingly widespread trend, as it allows for increased efficiency, quality, and safety in processes. However, it also presents new challenges in the design and manufacture of tooling that facilitates the handling of parts between different robots.

In this case, the challenge was to design a tool that would allow parts to be exchanged between two different collaborative robots at an intermediate step of the process. The first robot needed to remove the component from the packaging and place it in the tool, and the second robot had to pick up the component from the tool and insert it into its final assembly position.

The project’s goal was to design, manufacture, and validate a tool that met all customer requirements in a very short time, taking advantage of the benefits of 3D printing technology.

The solution to this challenge involved a comprehensive approach led by the Product Development team, from the detailed study of the parts to the practical implementation of the tool on the production line.

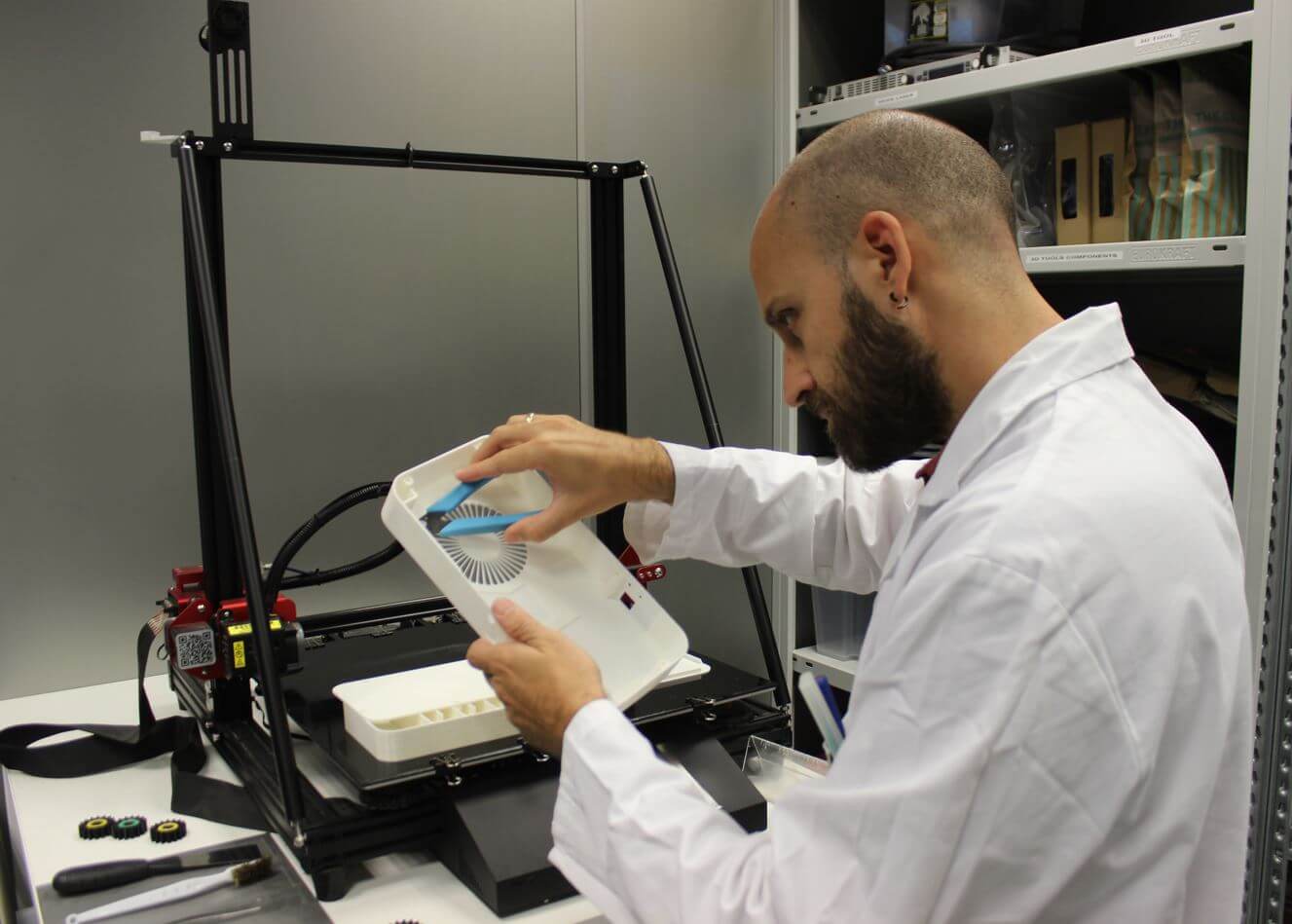

In the initial phase of the project, the team conducted a thorough analysis of the parts and proceeded to fully digitize the assembly line.

This critical phase aimed primarily to ensure that the tool’s design precisely adapted to the peculiarities of each element involved in the process. The team’s expertise combined with continuous interaction with the customer guaranteed an in-depth understanding of specific requirements, thus providing a tailored solution.

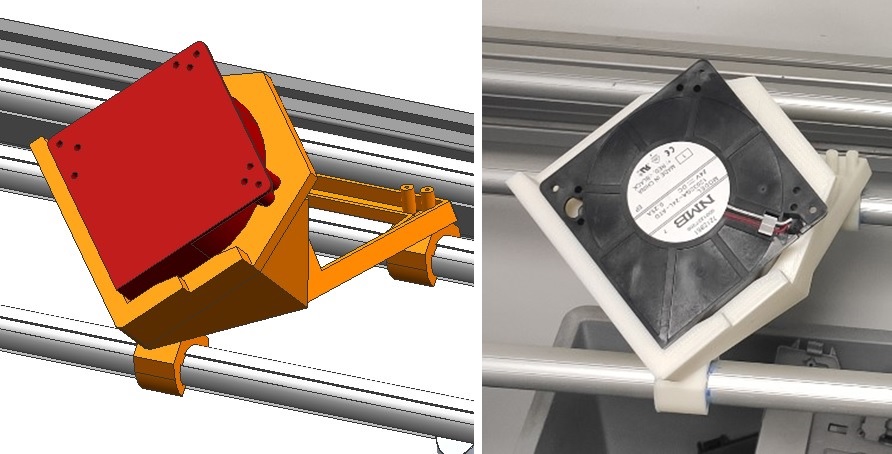

The mechanical development of the tool was tackled using advanced 3D modeling software. This choice ensured the creation of a design that was not only robust and efficient but also highly adaptable, facilitating precise self-positioning of the parts. The implementation of advanced modeling tools ensured not only the functionality of the tool but also its ability to adapt to possible variations in the production process, offering a versatile and durable solution.

The realization of this innovative design was achieved through FDM 3D printing technology, chosen for its speed in obtaining parts without compromising the quality needed to meet project standards.

This project is considered a success not only for meeting customer requirements but also for highlighting the agility and innovation of the Product Development team in designing solutions for industrial automation.