What was the challenge or problem to solve?

After a first inspection of the defective components, the forensic analysis focused on identifying the cause of the localized perforations in a specific area of the aluminum Al 1070 walls according to DIN EN 573-3 standard.

How was it addressed or what was the solution?

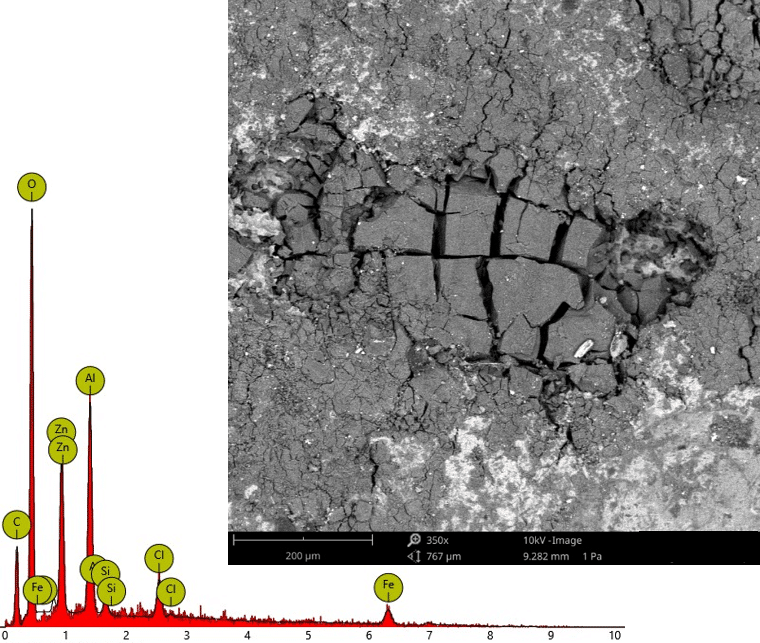

To know the failure mechanism, the damaged areas were analyzed using light and electron microscopy techniques (SEM and EDX) with a Phenom ProX de Thermofischer Scientific.

Thanks to this, the formation of a galvanic pair was found as a possible cause.

Once the main hypothesis of the cause of failure was formulated, accelerated laboratory reproduction tests of the failure were carried out in a climatic chamber.

Challenge

- Need to know the cause that generated perforations in the products

- Obtaining urgent results as they are critical components for the safety of the user of the product

- Proposed solutions to prevent the failure from reoccurring

Solution

- Microscopic inspection and characterization of the composition of the defective components

- Reproduction of the laboratory failure to validate the main hypothesis

- Implementation of short and long-term containment measures with the client