What was the challenge or problem to solve?

The mechanical properties of these pieces, and their behavior in the final application, depend largely on the amount of fiberglass it contains.

For this reason, the client requested to analyze certain components that failed, in order to find a correlation with their composition, and solve the problem.

How was it addressed or what was the solution?

This work was entrusted to our forensic engineering team.

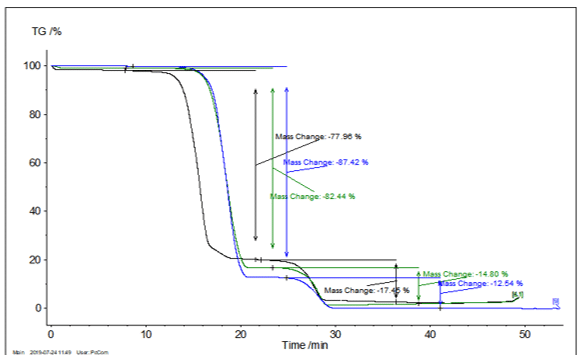

To find the cause of the breakage of the pieces, the material was characterized by thermogravimetry (TG).

With the results of the tests, the proportion of glass fiber contained in the different samples was determined, and in this way it was correlated with its mechanical properties.

Thanks to this information, I can find the cause of the failure, and solve it thanks to the definition of quality standards.

Challenge

- Finding the cause of failure of PA66 plastic parts on the assembly line

- Determine fiberglass content with high precision and minimal data dispersion

Solution

- Analysis of the material by thermogravimetric analysis

- Correlation of fiberglass content with mechanical properties and definition of quality standards