What was the challenge or problem to solve?

However, given the toxicity of ozone, we wanted to develop a system that would allow the elimination of residual ozone, achieving an effective sanitizing system, and at the same time safe.

How was it addressed or what was the solution?

The Materials Innovation team carried out a theoretical prospecting of the viability of all existing technologies for ozone degradation. From this, the three most suitable were selected to be tested experimentally.

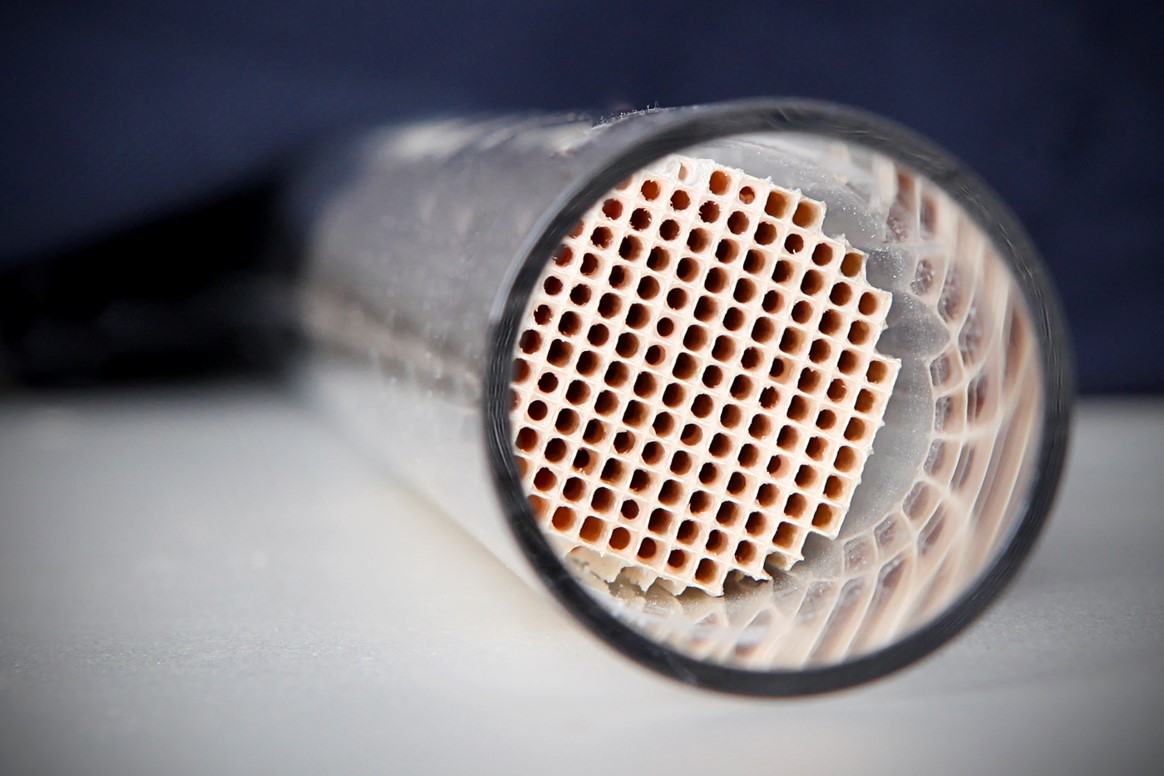

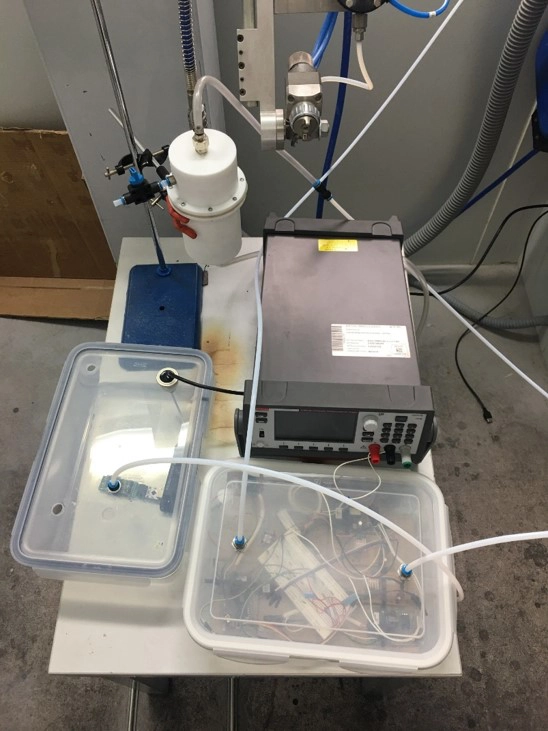

With the help of a custom designed laboratory setup, the effectiveness of different catalytic filters previously prepared in the laboratory could be evaluated. From these studies, its effectiveness to degrade ozone was known, as well as other parameters of interest (durability, resistance, kinetics …).

Once the study was completed, it was possible to provide a filter that met the requirements defined by the client, and capable of being manufactured on an industrial scale.

Challenge

- Eliminate residual ozone to have an efficient and safe system for users

- The selected solution had to meet the customer’s requirements and be an industrializable solution

Solution

- A survey of the state of the art was carried out, selecting the potential technologies to degrade ozone

- Catalytic filters of high effectiveness and easy industrialization were prepared