What was the challenge or problem to solve?

To identify the cause of the failure, a forensic analysis of several pieces was performed, carrying out tests with different analytical techniques.

How was it addressed or what was the solution?

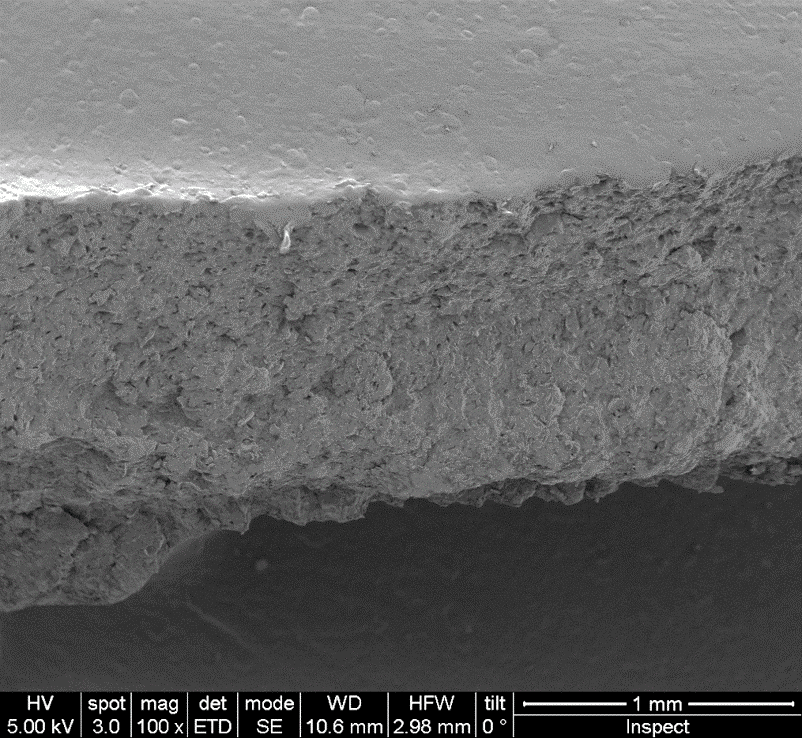

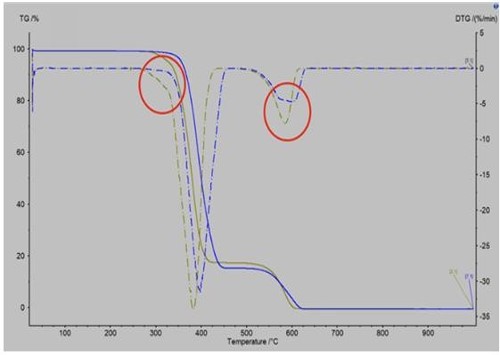

To find the cause of the fracture in the pieces, the affected area was analyzed with scanning electron microscopy (SEM). The material was also characterized with infrared spectroscopy (FTIR) and thermogravimetry tests (TGA).

With the results of the tests it was detected that the cause of the fracture was due to the lack of a stabilizer in the material. Taking this into account, the hypothesis raised was that the production process of the pieces had not been adequate.

Challenge

- Find the cause of breakage of plastic POM + PTFE pieces during transportation

- Propose a solution to prevent the failure from occurring again

Solution

- Investigate the material using forensic engineering techniques

- Carry out quality control of the pieces in a systematic way