What was the challenge or problem to solve?

Excessive breakages in some batches of polycarbonate plastic parts led one of our industrial customers to suspect poor conditions or some kind of failure in the execution of the injection moulding process of their parts.

INFINITIA’s Forensic Engineering and Failure Analysis Area proposed a study to investigate how the different conditions that may occur during a real injection process affect it. This approach required the injection of test pieces with different conditions in a pilot injector and their subsequent analysis and characterisation.

The first step carried out by INFINITIA in the resolution of this case was a bibliographic search in which different sources and databases were consulted that could guide and help to know the possible harmful causes that were affecting the polycarbonate.

Then, three different conditions were defined that could be the cause of the damage during injection: the humidity of the plastic, the residence time, the screw and mould temperatures.

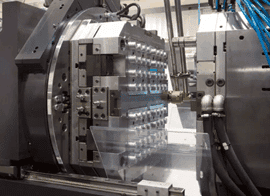

Once these potential conditioning factors had been defined, polycarbonate specimens were injected on a pilot injection moulding machine on the basis of these three factors.

Given that the client had observed that most of the breaks in the thermoplastic parts were broken at the time of washing, we then carried out a simulation of 10 washing cycles of the injected specimens with different injection conditions, proceeding to a subsequent in-depth visual observation with the aim of checking the existence of these possible breaks during the washing cycles.

Finally, to study how the injection conditions and washing cycles affected the mechanical properties, the INFINITIA team studied the mechanical properties of the injected specimens by means of the tensile test, applying the Universal Testing Machine (UTM) UNE-EN ISO 527.