What was the challenge or problem to solve?

In the field of electronic engineering, dealing with component failures is a constant demand that requires precise and effective solutions. The Materials team faced a failure analysis case to diagnose and understand the cause behind the breakage of an electronic component, specifically a silver flexible circuit, crucial to the functioning of one of our client’s devices. The complexity of this problem lay not only in repairing the damage but also in deciphering the origin of the failure to resolve it in production and prevent it from recurring in the future.

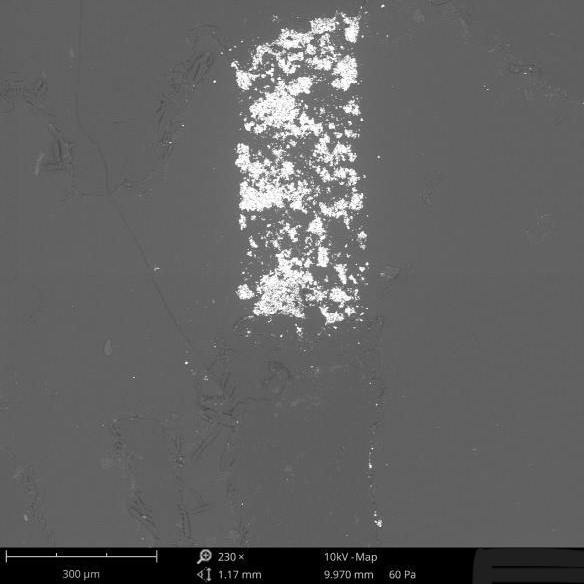

The project’s objective was to obtain a clear and detailed microscopic image of the defect. The task was significant: to compare the affected component with one in good condition to identify visual and structural discrepancies. The application of advanced microscopy techniques allowed us not only to see but also to understand the fundamental differences in composition that could have led to the failure.

The diagnostic and Forensic Engineering process began with the meticulous receipt and visual inspection of the affected circuit samples and a defect-free one. This first step was essential to establish a comparative framework that would guide the entire investigation. Subsequently, careful handling of these samples ensured that their structure was not altered before proceeding to examination under microscopes.

The analysis was carried out using two complementary techniques: optical microscopy and scanning electron microscopy combined with energy-dispersive X-ray spectroscopy (SEM/EDX).

These tools not only provided high-resolution images of the circuit surfaces but also allowed for a detailed analysis of the elemental composition of the damaged areas.

This study not only facilitated the precise identification of the type of damage but also helped implement preventive measures to avoid future incidents. The combination of SEM and EDX proved to be an effective solution for this type of analysis, enabling the client to take appropriate measures to resolve this incident as well as future ones that might arise in production.