What was the challenge or problem to solve?

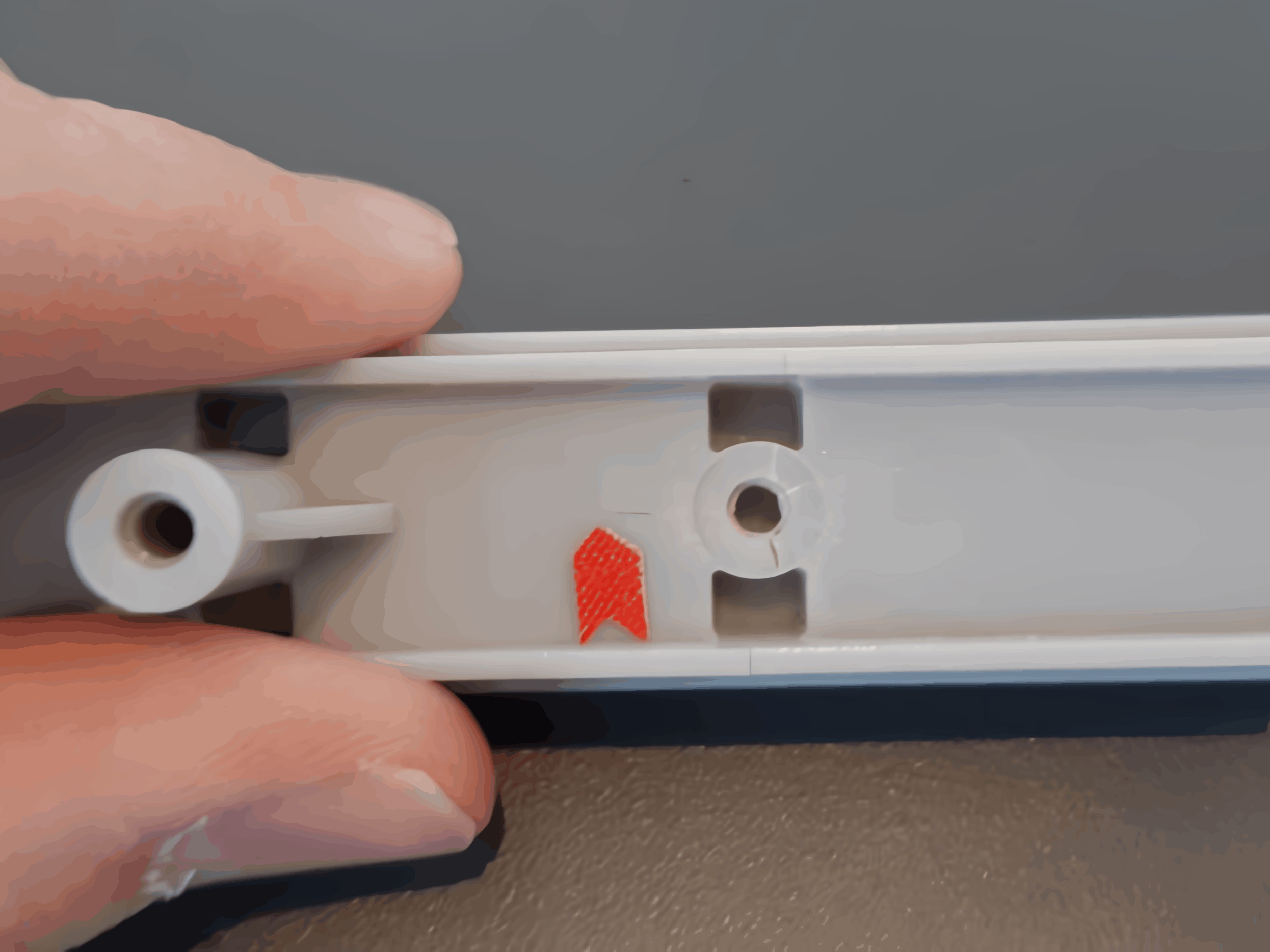

In the industrial sector, where precision and durability are crucial, even the smallest failures can have significant consequences. An example of this is the challenge a client presented to our forensic engineering team. After the installation of some new lighting components, concerning fractures were observed in the attachment areas. This issue not only threatened the structural integrity of the entire installation but also raised serious questions about the quality and safety of the design used.

The difficulty lay in identifying why these fractures were appearing and determining whether it was an isolated issue or a generalized failure that could affect the entire installation. The initial hypothesis suggested that the structural stresses in the combined materials (polymer and metal) used could be contributing to the problem. The goal was clear: to find the underlying cause of the cracks and develop solutions to ensure the safety and longevity of the lighting components.

The first step was to examine the physicochemical properties of the polymeric material where the fractures had been observed. Using advanced characterization techniques, the aim was to rule out the possibility that the affected parts were composed of a material different from that originally specified.

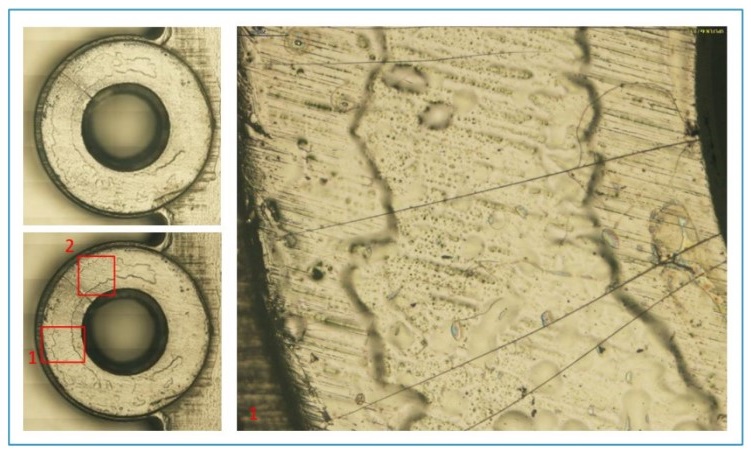

The next step was a detailed fractographic study of the cracks in the affected pieces. Through the use of high-resolution microscopes, the team was able to observe the fractures in detail, understanding their initiation and propagation. This analysis was essential to understand the nature of the cracks and their relationship to the design and materials used.

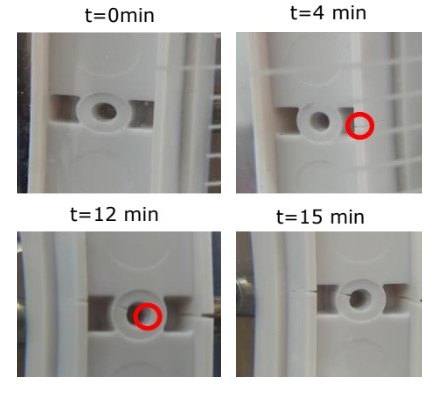

Finally, accelerated tests were conducted to reproduce the failure. These tests not only confirmed the distribution of stresses in the lamp assembly but also provided valuable data on how different conditions affected the integrity of the materials.

Thanks to these results, it was discovered that the processes of contraction and expansion suffered by the different elements of the assembly generated stress, weakening the material in the joint area and causing the fractures. This finding indicated that the failure was caused by the design, specifically in the tolerances, and/or the selection of materials, in terms of compatible contraction-expansion properties.

These discoveries provided valuable information for the client, not only to solve the current problem but also to optimize future designs, thus ensuring the quality of their product.