What was the challenge or problem to solve?

Overheating of an electronic device, and the use of materials that are not suitable for high temperatures, is a major problem that causes a multitude of failures on PCB boards.

In the case studied, it was detected that the temperature sensors gave an error that caused the inactivation of the cooling mechanism, so that the PCB board could exceed the recommended temperature limits and therefore cause serious damage to the product in the form of burns.

How was it addressed or what was the solution?

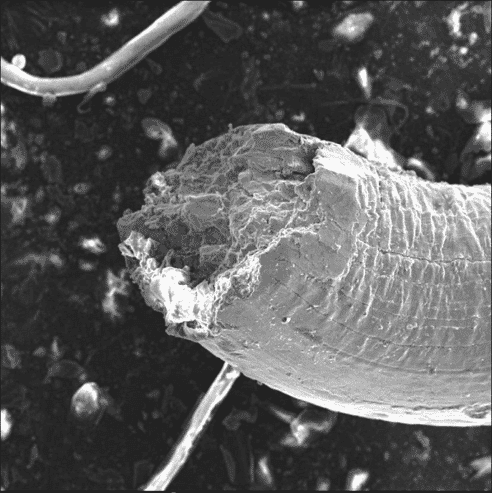

The key to detecting the failure was the analysis of the sensors through metallography in order to observe their condition. To do this, different samples coated with a conductive material (e.g. pure gold) were prepared and examined under a scanning electron microscope.

In the Forensic Engineering laboratory, we observed that the wires were embrittled due to the mechanical stress exerted by the insulation protecting the wires at high temperatures, which caused the conductor to buckle. We therefore concluded that this material was not suitable for sheathing the cables.

Thanks to the identification of the fault, we recommended materials that certify the correct operation of the sensors, avoiding possible combustion in the product.

Challenge

- Determine the cause of failures obtained in temperature sensors.

Solution

- Metallographic study of failed samples.

- Recommend changes in the materials used for coating.