What was the challenge or problem to solve?

One of the most interesting challenges that INFINITIA’s forensic engineering team has faced arose when one of our customers received a market claim because one of their products, specifically a polycarbonate plastic pipe (PC/ABS), had become brittle.

The challenge of the project was how to adequately characterize different samples in order to make a proper diagnosis and draw accurate conclusions.

Our forensic engineering team began the project with a basic characterization to locate differences in composition, organics or thermal properties that might indicate a change in the material. After this work, no differences were found.

Next, using more advanced techniques, the surface of the samples was inspected to assess whether microcracks had occurred and/or inorganic contaminants were present on the surface. Again, the result was negative.

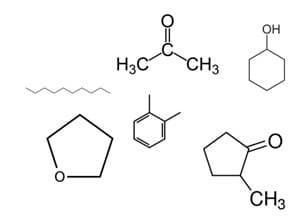

The next step was to identify the compounds adsorbed by each sample. To do this, a technique was used that forces the release of the compounds from the materials to be collected and analyzed by gas chromatography. This process made it possible to detect differences in the compounds released by each type of sample.

With this information, a literature search was carried out to determine the origin of the compounds released by the failing sample. It was concluded that the origin was due to the exposure of the samples to paint solvent gases and that the compounds released could cause embrittlement in the polymeric matrix.