What was the challenge or problem to solve?

How was it addressed or what was the solution?

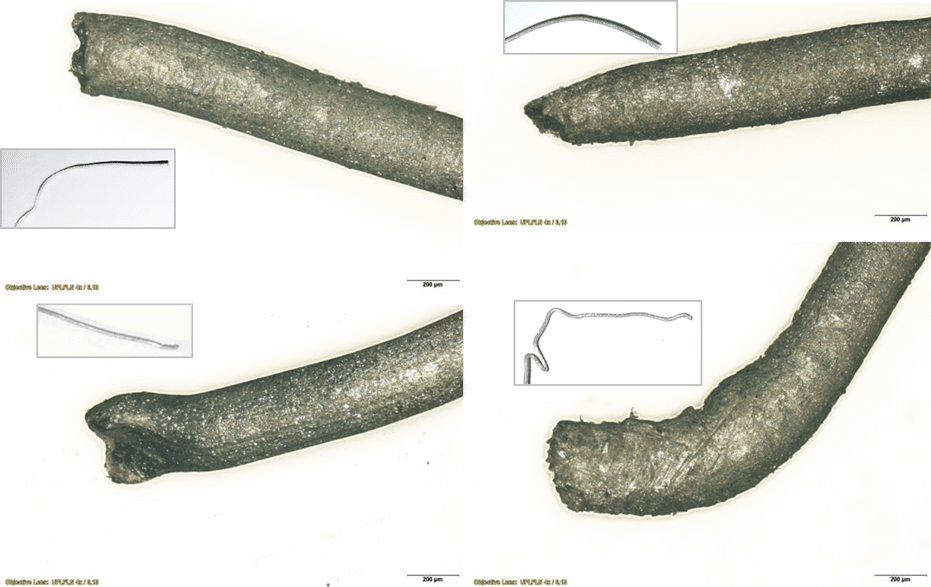

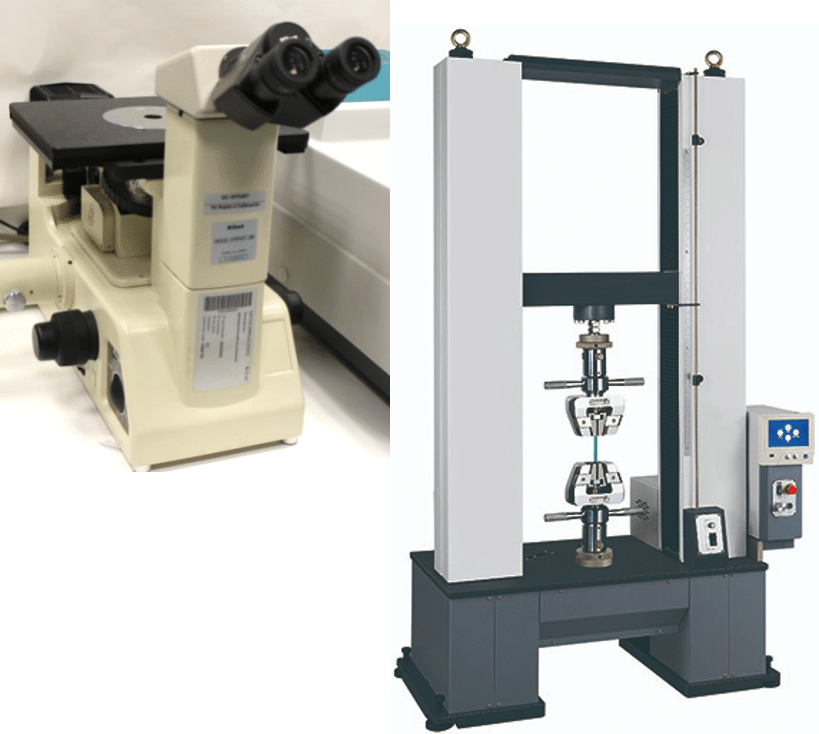

An analysis of the failure mechanisms of the broken conductors was performed by fractography with a Nikon metallographic microscope, identifying fragile, ductile and fatigue fractures.

All failure modes were validated with a universal testing machine according to IEC 60851-3:2009, reproducing in the laboratory the real operating conditions of the conductors.

Challenge

- Identification of the causes of the breakdown of conductors in real service conditions.

- Design of adapted experiments for the validation of the hypotheses of the causes of failure.

- Quantification of the mechanical resistance limits of the conductors in operation.

Solution

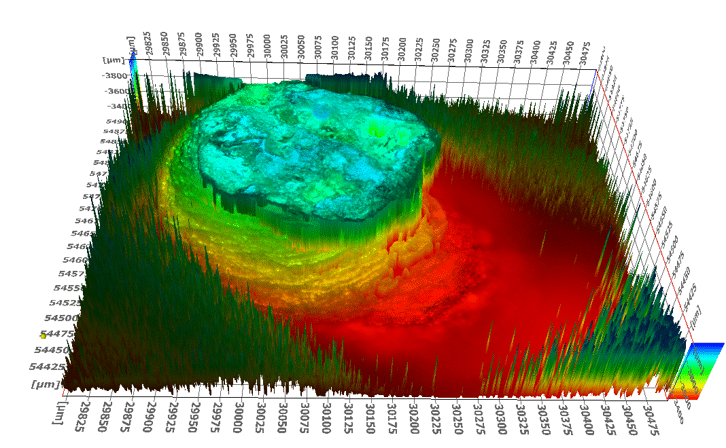

- Analysis by fractography on a microscopic scale of broken conductors.

- Laboratory reproduction of the failure mechanisms identified in the real samples.