What was the challenge or problem to solve?

This information allowed the client to optimize their process and optimize the different variables to minimize the generation of unwanted gases.

Unlike other works, in this application it was necessary to perform continuous analyzes, in order to monitor the gases generated at all times and thus be able to see minimal changes in different conditions.

Therefore, the client had the need to evaluate the sensory attributes of some food samples, which, in turn, were prepared in different ways.

How was it addressed or what was the solution?

For the detection of gases, a test bench was designed by the Materials Innovation team and a photoionization gas sensor (GX-6000) was used.

This detector was selected for these studies, because it allows detecting various types of gases, and with a very high sensitivity.

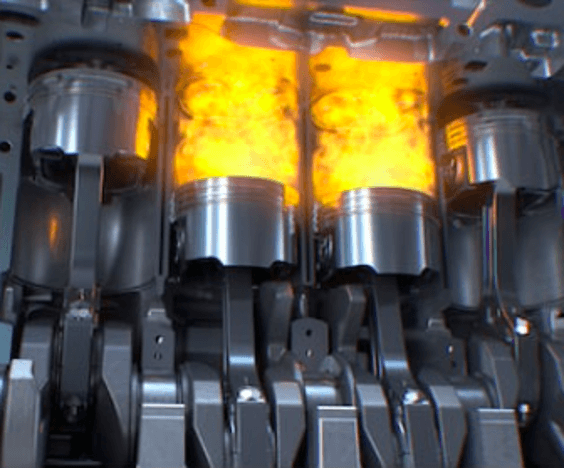

Challenge

- Gas analysis of a combustion process

- Low gas concentration

Solution

- Design of a custom assembly to analyze gases

- Gas detection using a photoionization sensor