What was the challenge or problem to be solved?

The main challenge faced by INFINITIA‘s Forensic Engineering team was the need to establish an efficient method to determine the hardness of galvanised steel components in production. The client had detected failures due to a possible variation in hardness, which did not meet the standards required from their supplier, compromising their integrity and usefulness in the production process.

The focus of this problem centred on a possible variability in the quality of the galvanising, which affected the final hardness of the product. The aim of the project was twofold: firstly, to identify the causes of the hardness failure through a detailed analysis of both unfit and fit parts; and secondly, to develop and establish an on-site test method that would allow effective separation of the parts according to hardness before their integration into the production line.

¿Cómo se abordó o cuál fue la solución?

To solve the problem, the Forensic Engineering team undertook a series of detailed steps to address the challenge in a comprehensive manner. Initially, the samples were prepared and visually inspected for possible defects in the homogeneity of the material.

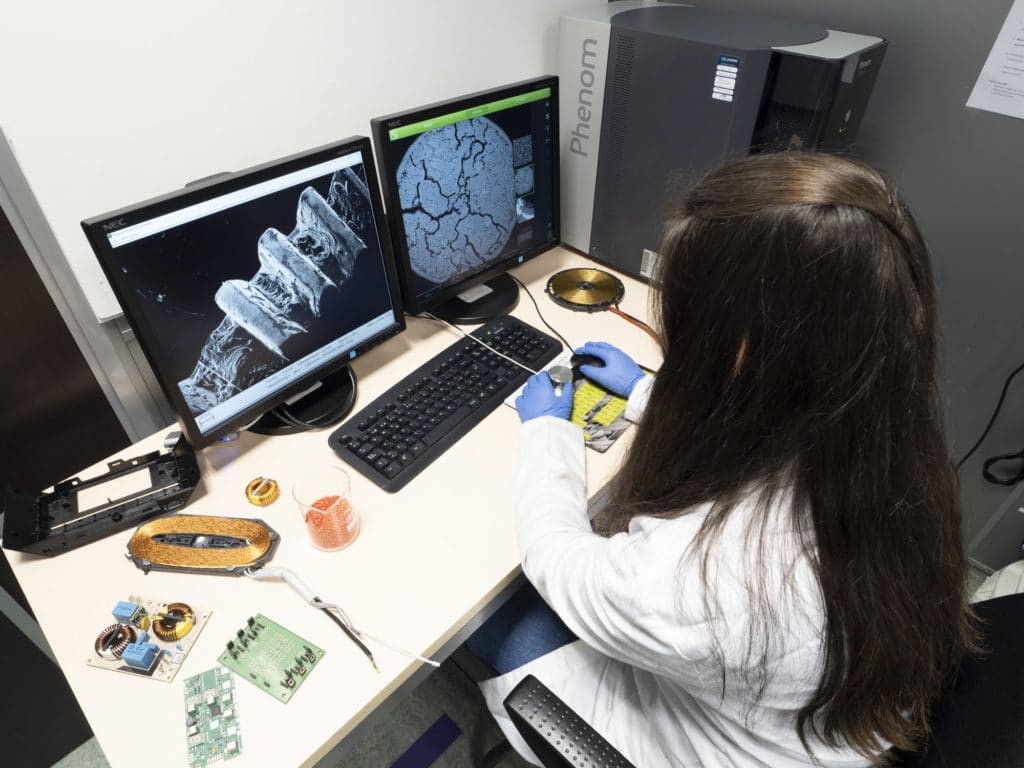

This was followed by a thorough analysis of the material using a scanning electron microscope (SEM-EDX), which allowed the team to identify differences in the composition of the samples and to detect possible inclusions or irregularities on the surface of the defective parts compared to the reference parts. This step was crucial to identify clues that could be the cause of the hardness failure of the parts.

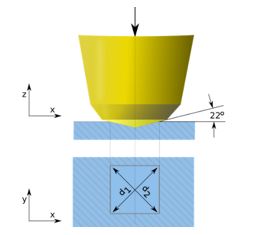

The next step was the measurement of the galvanising thickness on the parts classified as fit and unfit, using a Vickers hardness tester. This step helped to establish differences in the hardness of the steel in relation to the galvanising thickness. Once these differences were established, the relationship between the physicochemical characteristics of the materials and their hardness was analysed by integrating experimental data and relevant literature.

Finally, an in-situ method for the determination of hardness was developed using portable equipment. This approach allowed the customer to establish a direct correlation between the thickness of the electroplating and the hardness of the material, thus achieving an effective classification of the parts at the production site. This breakthrough was key to guaranteeing the quality of the final product and optimising the stages involved in the production process.