What was the challenge or problem to solve?

In this case, different functional steel coating treatments were investigated. The objective was to improve the wear experienced by a series of parts under the conditions in which they operated.

The client company, by means of a new surface treatment, was going to carry out a new application that required greater resistance to wear of the parts. For this reason, they contacted us to carry out this test and obtain results.

The project began with a search for the state of the art in the field of coatings and surface treatments. This preliminary study is an essential step in any research process, as it allows us to locate existing knowledge on a given topic. The first approach was very important, because it would allow us to select the best alternatives for subsequent evaluations. In this phase, we resorted to the search for different existing commercial solutions, as well as patents and published scientific articles.

In order to ensure the best conclusions, the test had to be carried out on real samples. For this reason, we contacted suppliers and distributors to obtain samples on which to evaluate the coatings.

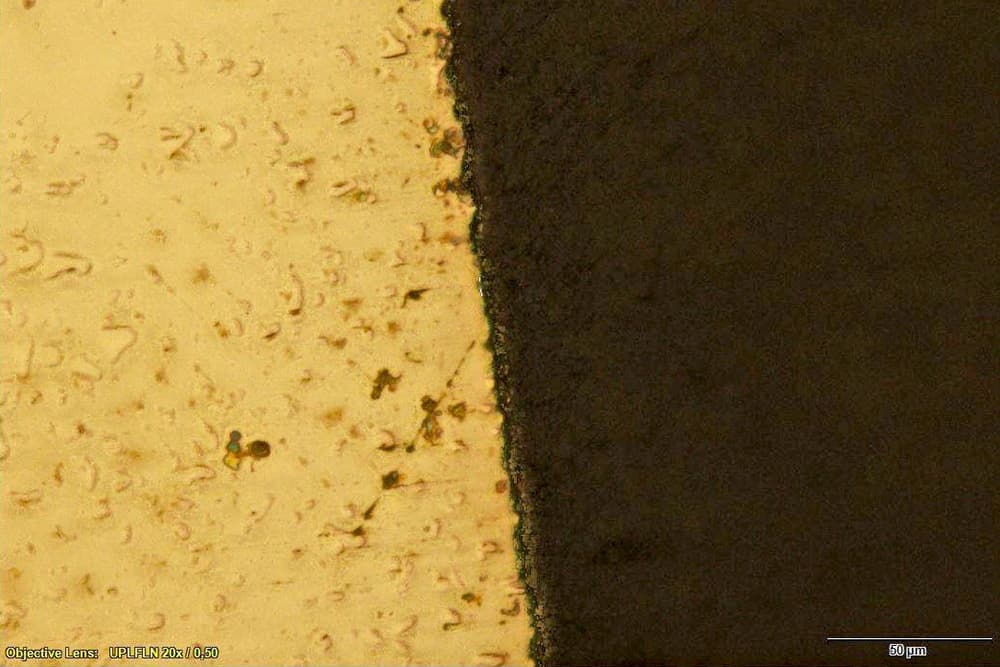

From these samples, experiments were carried out using different techniques: X-ray fluorescence (XRF), which makes it possible to determine the elemental composition of the materials, optical microscopy, which makes it possible to observe the microstructure of the materials, scanning electron microscopy (SEM), which provides information on the topography and composition of the samples and, finally, several abrasion and wear tests.

In the final part, a comparison of the functionality of the different coatings evaluated was carried out. In view of the results and the cost provided by the different alternatives, the optimum coating for product improvement was selected.