What was the challenge or problem to be solved?

INFINITIA’s Forensic Engineering team was faced with the challenge of finding high temperature adhesives to replace the one currently available to the customer in the production process.

The current adhesive, designed to withstand high temperatures, was soon to be withdrawn due to the imminent entry into force of a regulation prohibiting its use. This restriction created an urgent need to identify a substitute that would maintain the same properties at high temperature, without compromising the bonding capacity between the elements in the working environment.

The context of this project focused on finding a solution that would not only meet the new regulatory requirements, but also demonstrate equal or superior behaviour in terms of performance under extreme use conditions. The objective was to select viable high-temperature adhesives and evaluate their performance through accelerated life testing to ensure they would withstand the ageing and thermal cycling typical of the customer’s operating environment.

How was this approached or what was the solution?

To address this challenge, the INFINITIA team carried out a careful selection of adhesives based on datasheets provided by various suppliers. After a thorough review of the materials available on the market, those adhesives were chosen that, according to their specification, were indicated to withstand the working temperatures required by the customer’s product. This first step was key to ensure that the selected alternatives had the potential to meet the thermal resistance requirements.

Samples of the selected adhesives were then subjected to accelerated ageing tests, using specialised laboratory equipment. The samples were exposed to cycles of thermal shock and washing, simulating several years of use under extreme working conditions. This process allowed the behaviour of the adhesives to be evaluated against factors such as thermal degradation and moisture wear, ensuring that their durability was comparable to that of the adhesive they were intended to replace.

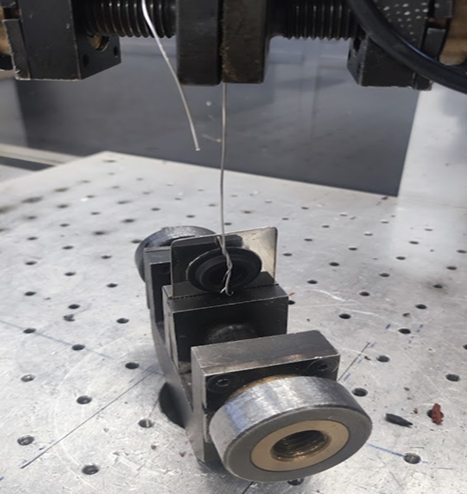

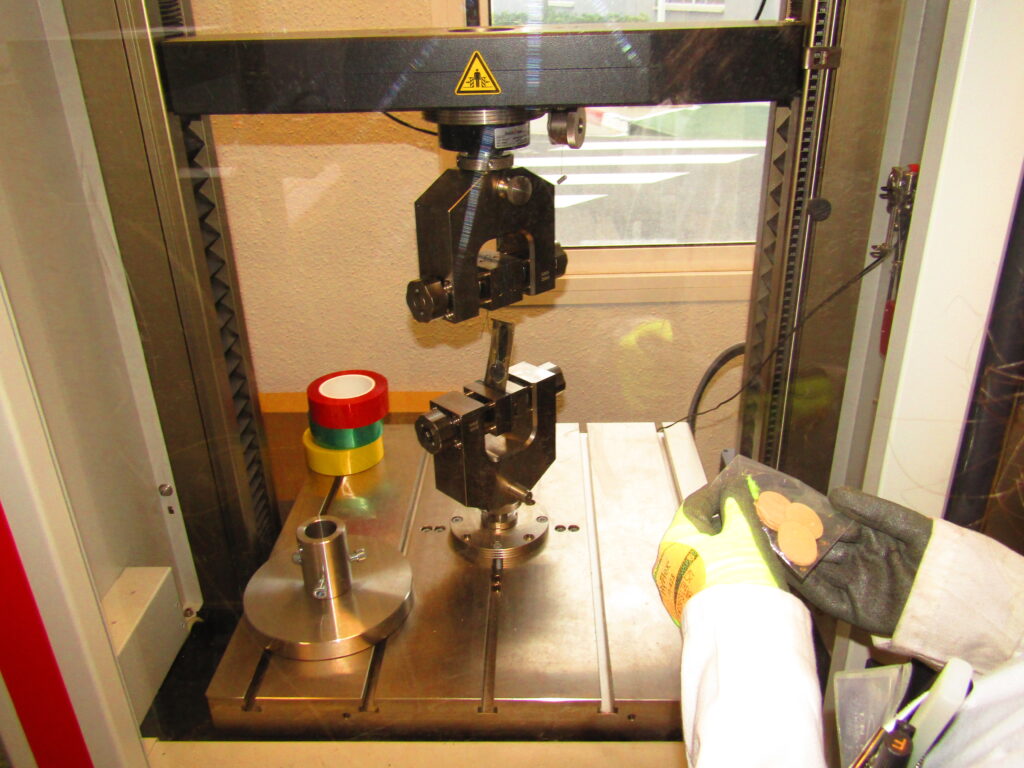

Finally, the adhesion properties of the materials were evaluated by mechanical testing on a universal testing machine (UTM). The bond strength of the samples was measured after the ageing cycles were completed, allowing to determine whether the high-temperature adhesives maintained their bonding strength under the required conditions.

As a result, the INFINITIA team was able to identify viable alternatives that met technical and regulatory requirements, providing the customer with reliable options for adhesive replacement without compromising bonding performance.