What was the challenge or problem to solve?

The forensic engineering team at INFINITIA faced the challenge of identifying unknown acid contaminants present in a polymeric matrix. This compound adhered to samples at an unknown stage of the manufacturing process, contaminating the material and resulting in defective batches that the client had to withdraw.

The project’s objective was twofold: to precisely identify the contaminating compound and determine the specific phase of the manufacturing process where the contamination occurred. Solving this problem would not only eliminate the risk of future contaminations but also ensure the quality and safety of the manufactured products.

The first step was to gather detailed information through meetings with the client about the material’s production process. This data helped narrow down the possibilities regarding the contaminant present in the samples.

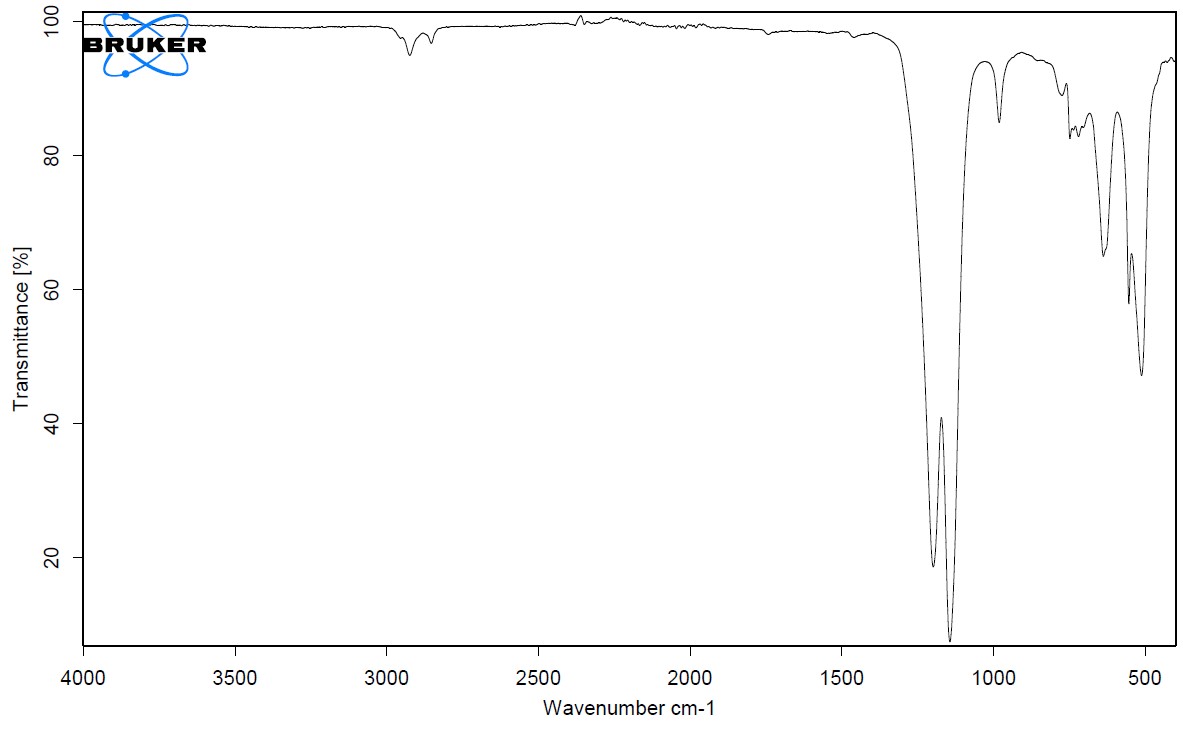

Subsequently, an analysis was conducted using infrared spectrometry (FTIR). This analytical technique was crucial for identifying the different functional groups present in the samples.

By comparing contaminated samples with uncontaminated ones, it was possible to determine the specific functional groups of the contaminant, which allowed for the identification of the compound’s family and finally discovering the substance causing the contamination.

Finally, an analysis was performed using gas chromatography – mass spectrometry (GC-MS), which provided a quantitative concentration of the contaminating compound.

This comprehensive approach not only led to the successful identification of the contaminating compound but also revealed the specific stage of contamination in the manufacturing process. This finding enabled the implementation of corrective measures to prevent future contaminations, thus ensuring the quality of the manufactured products.