What was the challenge or problem to solve?

A customer wanted to introduce a new process of laser ablation to remove paints in factory. Specifically, through selective laser ablation to create new backlighting effects on certain components.

INFINITIA carried out a complete characterisation and quality analysis of different paints for a new industrial application related to the backlighting of a coating. With this, we helped our client to select the process that was best suited to the requirements.

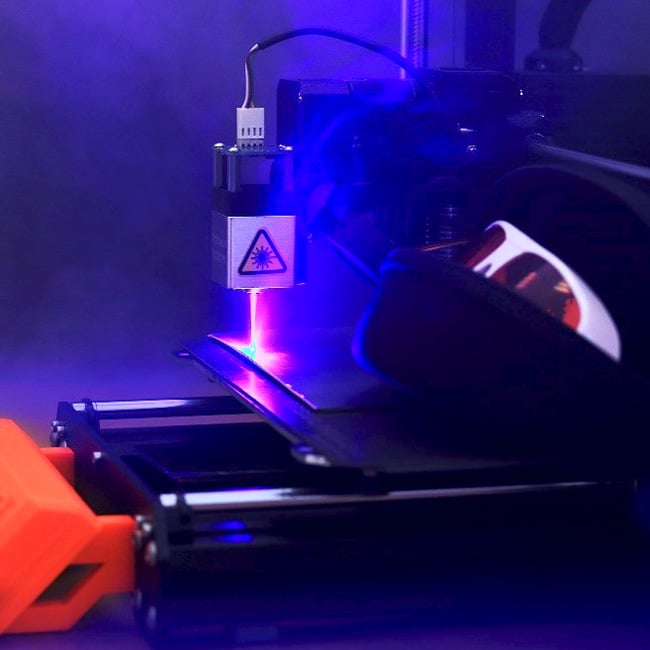

Specifically, the technology proposed by the client required the use of a laser with very specific characteristics. The laser beam had to remove certain layers of paint, but without remaining too long on the material so as not to burn the rest of the layers.

INFINITIA’s Materials Innovation area evaluated different paints and procedures in depth in order to design the ideal industrial process. In addition, the research allowed us to detect and prevent possible problems that could occur in this selective laser ablation.

Laser ablation of paints to create new backlighting effects

After a literature search, the parameters were optimised in order to study the effect of laser radiation on the different samples.

We began the tests by analysing the light transmittance and the colour variation of the light in the area treated with the laser. This technique allows us to precisely identify the alterations produced by the laser on the material. Next, we studied the behaviour of the paint after being adhered to the base material.

Finally, we visualised the laser-treated area with a microscope. Through this observation, we were able to determine the amount of paint that had been removed in the different layers and to reveal possible problems that could occur in the future.