What was the challenge or problem to solve?

In the current industrial world, there are constant challenges to improve the aesthetics and functionality of products. The materials team faced one of these challenges, focusing on creating laser microperforations in laminated aluminum.

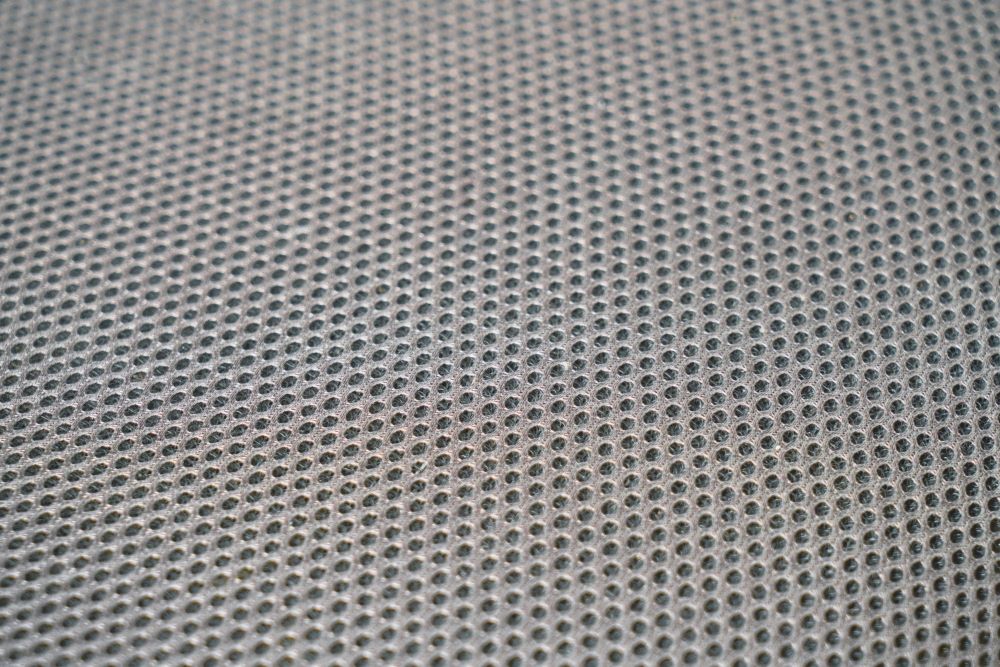

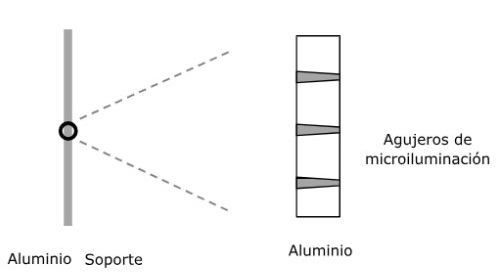

The goal was to achieve a backlighting effect through these perforations, which in turn should be practically invisible to the human eye when the system is off. This challenge arose in response to a market need where existing backlighting techniques did not fully meet the required aesthetic and functional demands.

To tackle this challenge, INFINITIA’s Materials Innovation team conducted an extensive literature review to determine the optimal size of the holes, considering the final application of the pieces and the limits of human visibility. A state-of-the-art ultrashort pulse laser was selected, as it offered superior quality in micro perforation and high absorption, essential for achieving quality holes without burrs or oxidation.

The choice of material was also crucial. Laminated aluminum, widely used in the sector and suitable for acting as an illuminable interface when microperforated, was chosen. The experimental phase involved designing tests to explore the capability of the selected laser, using different modes of pulse exposure, and its interaction with the aluminum.

To ensure precision, optical microscopes were used to measure the dimensions of the perforations and analyze the light transmission through them. Additionally, a Scanning Electron Microscope (SEM) was used to observe the interior of the holes and detect possible defects.

Microperforations were achieved that met all the client’s aesthetic and functional requirements. This project not only solved a complex technical problem but also opened new aesthetic possibilities for the client’s future applications.