What was the challenge or problem to solve?

The challenge faced by the company INFINITIA focused on creating a product that combined functionality and aesthetics in a novel and effective way. The client desired a decorative element that, when the lights were off, maintained the natural appearance of a wooden sheet, but when turned on, revealed a specific design through backlighting. The key was to ensure that the illuminated design was invisible when the light was off, thus presenting a dual aesthetic and functional state.

To tackle this challenge, the INFINITIA Materials Innovation team adopted a methodical and highly technical approach. The solution began with the careful selection of the hole size, using extensive literature to determine the dimensions that best suited the project’s aesthetic and functional needs.

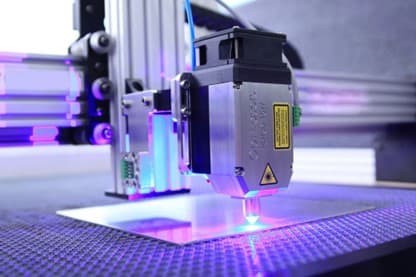

It was essential to select a laser that minimized any possible defects, which was key to maintaining the quality and invisibility of the microperforations.

The selected material had to be not only compatible with the laser microperforation technique but also capable of supporting the installation of lighting systems behind it without altering its integrity or appearance. An ultrashort pulse laser was used to optimize the perforation process, adjusting the exposure parameters to maximize precision and minimize any potential damage to the material.

The results were evaluated using advanced microscopy techniques and a Scanning Electron Microscope (SEM) to ensure that the dimensions and quality of the holes met expectations. These measurements allowed real-time adjustments to the processes, ensuring that each step aligned with the desired light transmission objective. The design of the pieces was adapted using specialized software and CAD, and finally, state-of-the-art laser drilling was employed to create the final samples.

The benefits of this project were significant, as it not only achieved the goal of creating a backlit design that was invisible when turned off but also established a new standard in the use of microperforation techniques for decorative and functional applications.