What was the challenge or problem to solve?

Our client was developing a new product based on an innovative business idea, but its prototype showed deficiencies in its mechanical behaviour, requiring a mechanical design improvement. These deficiencies were so significant that they compromised the viability of the product, as it broke within a range of operation considered normal.

The Product development team faced two main challenges: the lack of quantitative reference data, which forced the performance of qualitative simulations based on comparisons with test models, and the geometric and volume constraints of the product, which limited the options for design improvement.

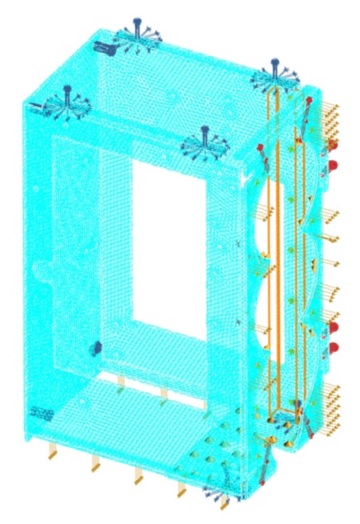

The improvement process began with the reception of the product our client was developing and a detailed analysis of the actual load case, followed by the creation of hypotheses for the simulations. By using real use tests and disassembling the product to review its structural elements, the team was able to gain a deep understanding of the challenges faced. This stage was crucial to simplify the collected information and create a 3D model that would serve as a reference.

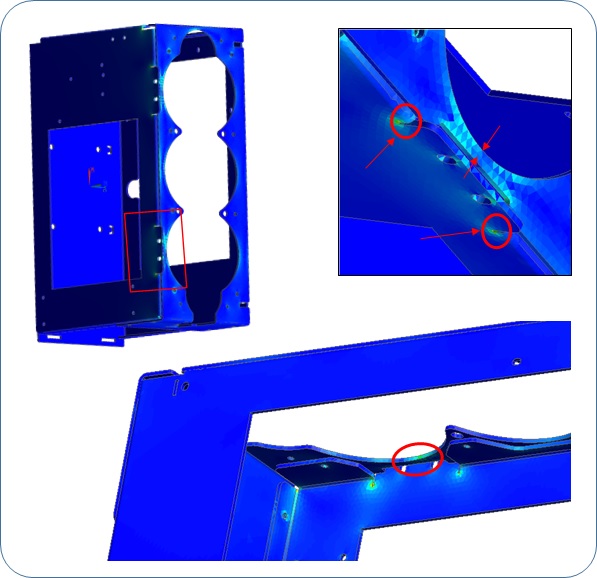

With the 3D model and simulation software, the boundary conditions and loads were established to simulate the stresses to which the original model was subjected. This step was fundamental to execute simulations that provided a basis for generating improvement proposals.

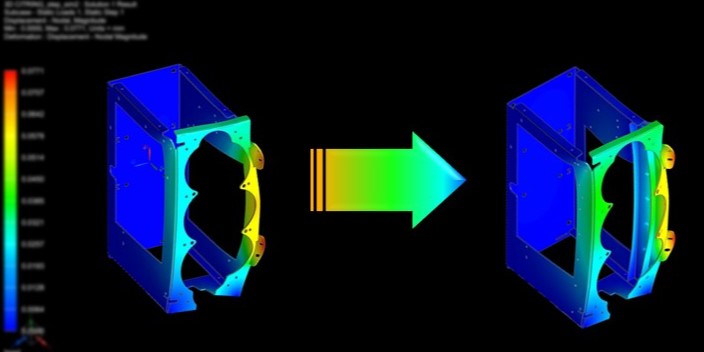

Through an iterative process, the mechanical behaviour of various design proposals was simulated, comparing their results with the original model to assess the effectiveness of the proposed improvements.

The success of the project was materialized in the presentation of several design proposals that not only met the established requirements and adhered to the geometric constraints but also offered improvements in the product’s structural resistance between 30% and 52%. This achievement not only demonstrated the technical capability of the team to face and overcome complex challenges through innovation and the use of advanced technologies but also ensured the viability of a product that promises to revolutionize its market segment.