What was the challenge or problem to solve?

INFINITIA’s Product Development team faced the challenge of assembling and programming a customized sensor to measure several parameters. The customer, a company in the industrial sector, needed to perform several measurements using a single sensor.

The challenges associated with this work were, on the one hand, to mount the sensor in the scenario where it was going to be used and, on the other hand, to program this sensor to display and store the results collected.

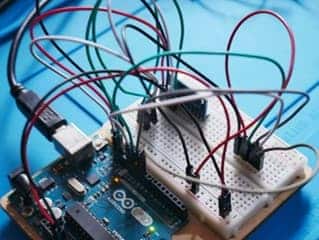

Starting from the different datasheets, the electronic schematic was designed to define how all the connections were to be made. The sensor was then programmed by means of a specific data collection software, by means of which the data of the parameters of interest to the customer could be obtained and recorded.

Once the system was programmed, a graphical interface was created using visual graphical programming software. This task was carried out to facilitate the usability of the sensor, since the user could see on the screen, at all times, what data was being collected. In this way, he could also establish when the collection of these data started and ended.

Finally, the final assembly and start-up of the sensor was carried out using different electronic components and a computer. This step was carried out in situ, in the scenario proposed by the client, so that he could control different parameters on the screen.