What was the challenge or problem to solve?

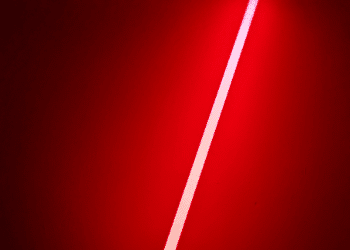

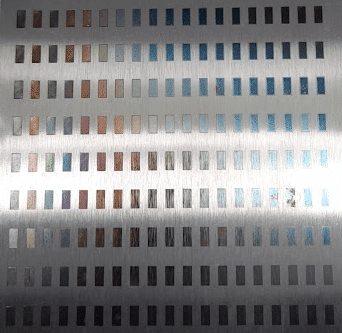

The process of painting a metal, in one or several different shades, conventionally requires the use of specific and costly paints. From Infinitia’s materials innovation team, it is possible to replace these conventional processes with laser marking and achieve a wide range of colors.

How was it addressed or what was the solution?

To achieve the different colors, the aim is to generate stable oxides that give the different shades to the metal. It is a process that depends mainly on the material and the control of two parameters: speed and frequency. The result is a surface colored according to the desired design.

The implementation of laser as a digital decoration technology, means the implementation of a cleaner technology by not having to use chemicals or consumables, greater safety for workers, as well as its ease of implementation in factory processes.

Challenge

- Coloring a metallic surface without the use of inks or chemicals

Solution

- Use of laser technology

- Optimization of parameters in order to achieve the desired finish.