What was the challenge or problem to solve?

In the progress to the top of its optimization, it is easy to stumble over some steps, such as the appearance of “defects” like voids or corrosion.

How was it addressed or what was the solution?

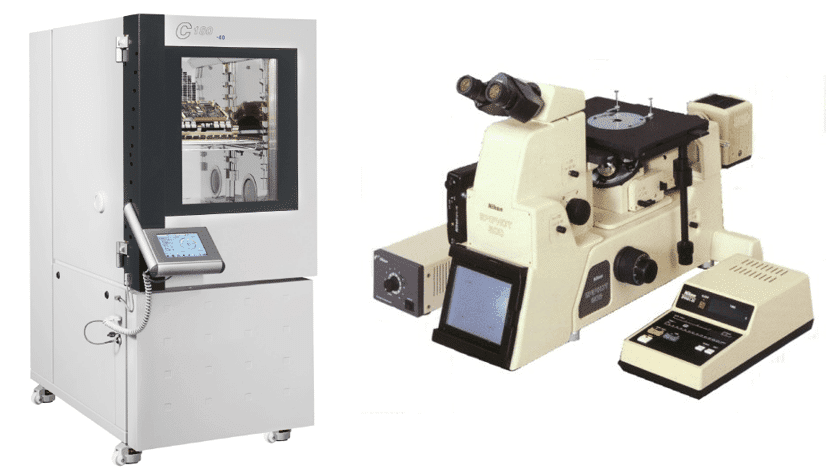

For this case, life tests were carried out by reproducing the real humidity conditions in a climatic chamber, in order to identify the most critical areas of the parts after stamping and welding, and successive optimizations of the welding parameters of the platform were carried out with their corresponding metallographic analysis before and after, which were decisive in improving the quality of the weld and the consequent service life of the complete product.

Challenge

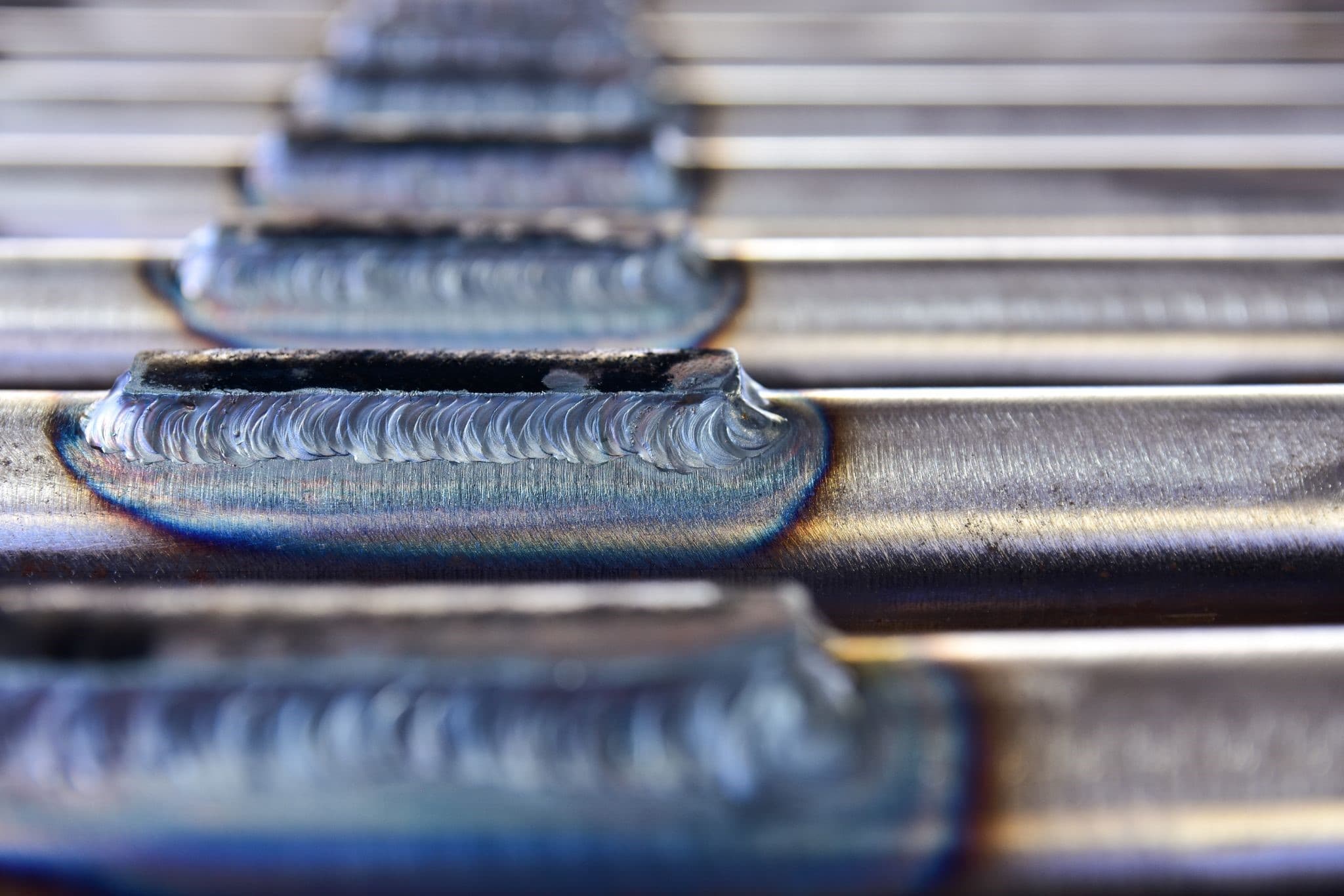

- Design of a quality welded joint between two dissimilar stainless steels

- Validation of weld durability in a laboratory accelerated manner

Solution

- Definition of a test bench to identify the best combinations of welding parameters

- Characterization of the joints by metallography and mechanical strength, before and after life tests