What was the challenge or problem to solve?

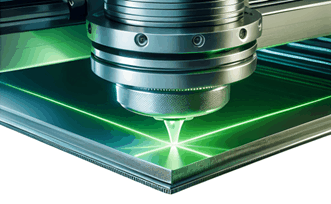

INFINITIA’s materials team faced a challenge in the field of laser cutting. The project required the optimisation of laser parameters for cutting multilayer films.

Initially, an extensive literature search was carried out to understand the fundamentals of laser cutting on multilayer materials. This step was crucial to establish a solid foundation on the processes involved and the existing technologies.

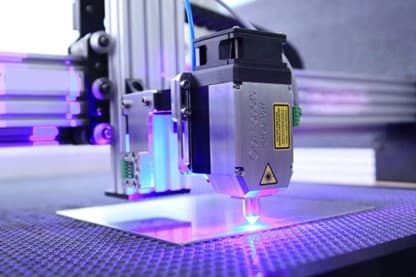

Subsequently, the INFINITIA team proceeded to optimise the laser parameters, using an ultra-short pulse (femtosecond) laser. This advanced technology was essential to achieve precise cutting of the films without causing melting or damage to the inner layers.

With this information, the laser parameters were iterated and rectified. This fine-tuning process ensured that the laser performed optimally according to the specific characteristics of each material.

Finally, a rigorous check was carried out to ensure that the cut parts were not damaged by the laser. The customer validated the correct operation in production with the selected parameters, thus confirming the success of the project.