What was the challenge or problem to solve?

In this case, the aim was to modify the plastic used in the food industry to extend the shelf life of foodstuffs.

How was it addressed or what was the solution?

According to our work methodology, the first action to take was to analyze the current materials and identify the cause of oxidation in the food. Once the forensic engineering team determined that the cause was the diffusion of oxygen inside the package, it was time to innovate in materials.

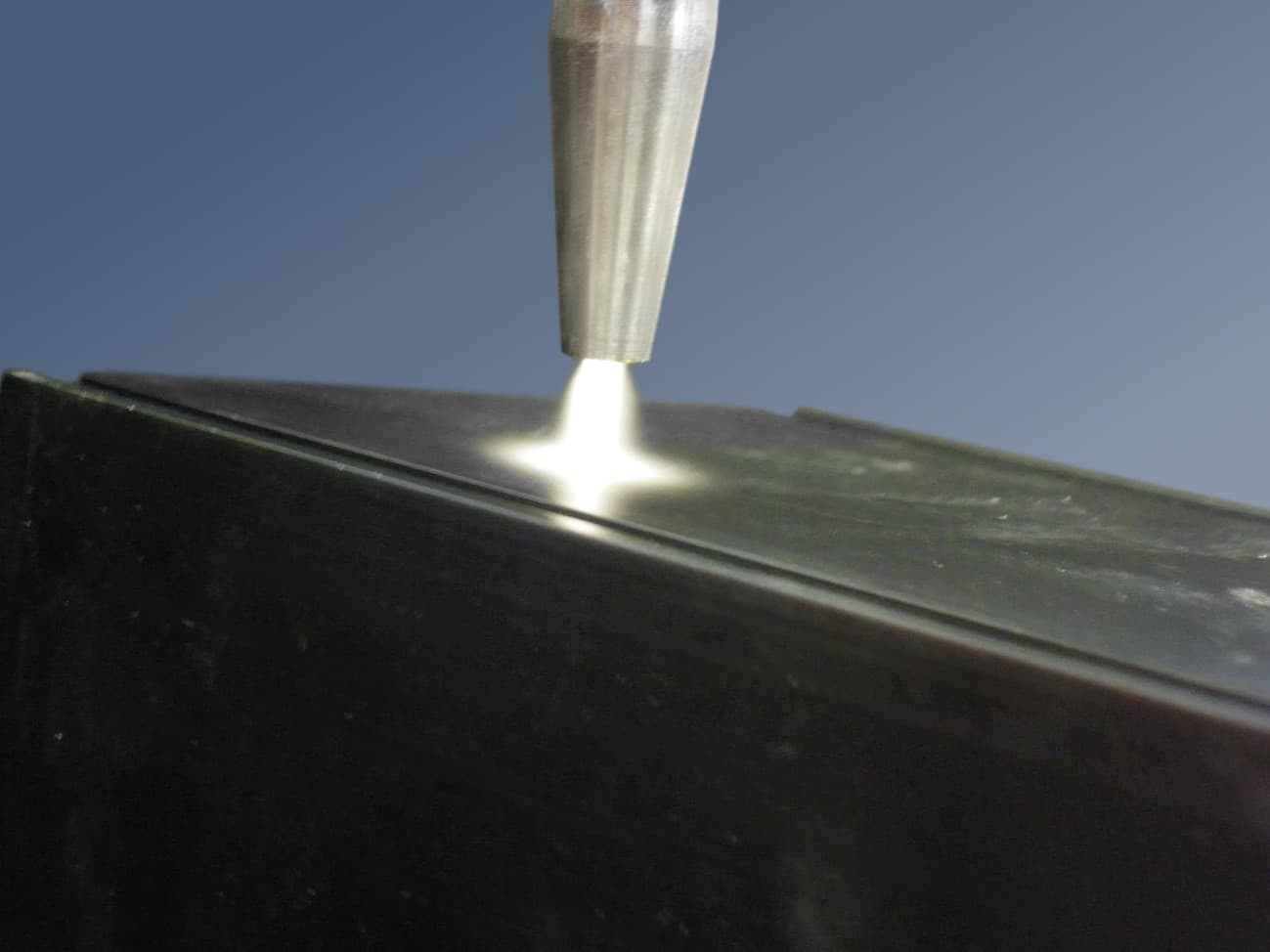

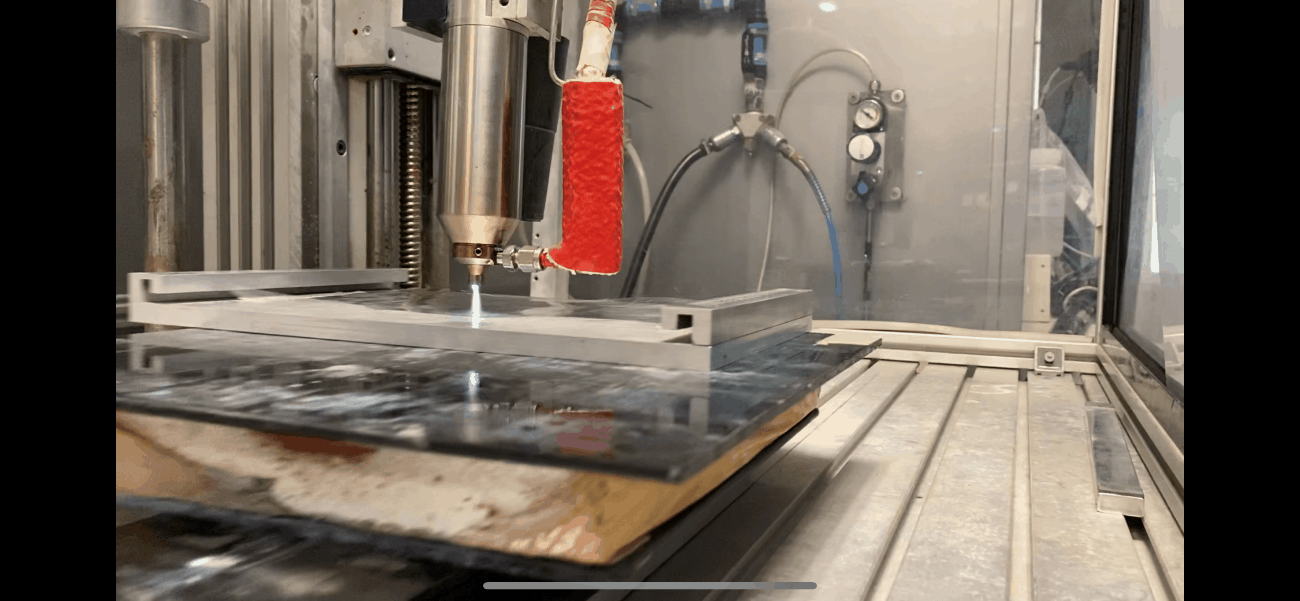

Our approach was the deposition of silicon oxide, which reduces oxygen diffusion by several orders of magnitude. This process is usually performed using chemical vapor deposition (CVD) equipment that requires high vacuum conditions, which is unfeasible for large production runs. As an alternative, we investigated the possibility of performing the process with atmospheric pressure plasma jet (APPJ) equipment, which does not require critical conditions of use.

Challenge

- Identifying the cause of food spoilage

- Modify packaging to extend product shelf life

- Integration of the solution into the manufacturing process

Solution

- Analysis of the materials used

- Coating on films with non-permeable layers

- Synthesis with industrially deployable equipment