What was the challenge or problem to solve?

Thanks to these simulations performed by the Product Development team, it could be ensured that possible surface or functional defects related to part geometry or mold configuration could be detected.

How was it addressed or what was the solution?

The process of creating a plastic part can involve multiple variables and parameters to be analyzed, whose costs in time and money are high, either from the point of view of the mold manufacturing or from the point of view of the injection process.

However, by using injection simulation tools, the part filling process was analyzed and possible defects that could be corrected in time by redesigning the part or the mold were detected.

Challenge

- Detect possible surface defects on parts before their release to production

Solution

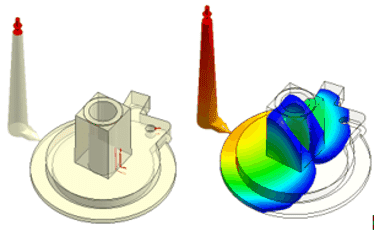

- Simulation of the plastic injection process

- Geometric analysis of the part

- Analysis of part filling, process parameters and mold cooling