What was the challenge or problem to solve?

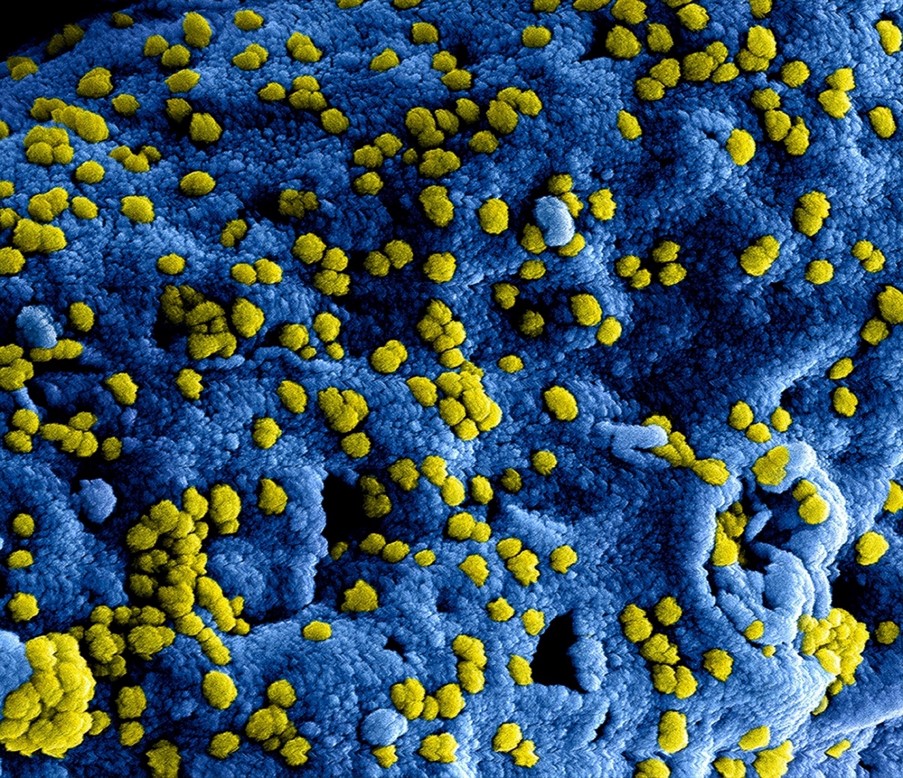

To prevent this, the Materials Innovation team carried out a development for the additivation of certain plastic and elastomeric materials with new active ingredients that prevent the growth of bacteria and other microorganisms.

How was it addressed or what was the solution?

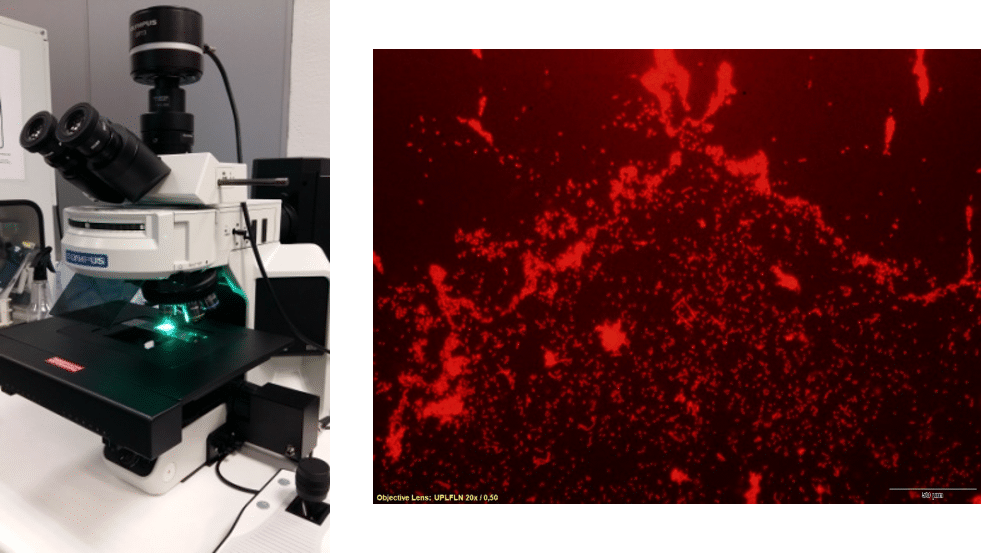

The development was approached studying the processing conditions that affected the additive and that could degrade it, as well as different alternatives to protect it and increase its stability (encapsulation, addition of porous fillers …)

Once the critical parameters of the processing were identified, an intensive study focused on these parameters, as well as a complete characterization of the material and additive, was carried out.

During the optimization stages, successive characterizations of the material were carried out, of its mechanical, physical-chemical properties, as well as its effectiveness to protect the surface from bacterial growth through microbiological analysis techniques (according to international standards such as ISO 22196:2011).

Challenge

- Inclusion of a new antimicrobial additive in the production of plastic parts

- Optimization of the processing parameters to avoid their degradation

Solution

- Selección de estrategias para mejorar su estabilidad durante el procesado (encapsulamiento, adición de cargas porosas…)

- Optimización de los parámetros de producción para asegurar la máxima efectividad de la pieza final