Since facing this challenge individually would not allow us to obtain a global vision of the problem, we decided to approach it by creating a specific and multidisciplinary team. In this way, all the competences needed to solve the challenge have been integrated: User and Market Research, Food Technology and Engineering, and Product Design and Prototyping.

The following is a description of the tasks that this team, in this case, of three departments, intends to perform -through a technologically improved object- to make life easier for a future and indirect consumer.

Flavored waters are a trend in constant growth and consumption. Today, as a consumer, you can choose how you prefer to acquire them; you can buy them in large supermarkets ready to be consumed or, on the contrary, you can venture into the home process marked by the mandates of “healthy” and “no consumption of ultra-processed products”, having the option of making them at home in the “home-made” style.

The first step in this challenge was to assess consumer needs and identify insights. This has been achieved through interviews and conversations with real users from different European countries, obtaining key insights. In parallel to the study of consumer needs, market research has been carried out to identify the potential business model. The preference for healthy flavored waters was clear. Now, was there a new product idea that would facilitate consumption without the need for the public to engage in costly and traditional preparation?

From this point on, we did not create a product from scratch, but we studied how to improve, thanks to materials and technology, the elaboration process and its final result.

Different types of homemade infused beverages made in different European countries.

(Photos from consumer interviews and focus groups)

2. Food technology

The materialization of the product involved, in a second phase, translating the identified needs of the consumer into technological solutions through the Food Technology team.

As a result of the consumer study, the color and taste of the water, as well as the time required for its preparation, were identified as points to be improved. To this end, different technologies and processes were proposed to improve the conventional preparation process and the final quality of the water.

To achieve the desired results, physicochemical and sensory parameters of the waters were characterized with the different technologies applied. Among the quality control analyses, pH, conductivity and viscosity were analyzed as physicochemical parameters. In the sensory tests, blind tastings were carried out with trained panelists who were able to provide solutions to this first test and, after hearing their opinions, make the appropriate modifications.

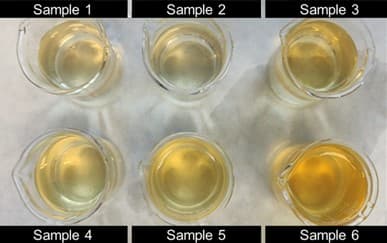

Samples of infused waters prepared by conventional and optimized methods prior to physicochemical and sensory characterization.

3. Product design and prototyping

One of the main challenges in this area was to integrate components found in the market, i.e. “commodities”, into the device. Using laboratory components was not feasible due to their complexity, price, size or weight. We had to look for more accessible components and adjust the parameters that related the physical-chemical properties of the water (color, flavor intensity, sweetness, acidity…) with the parameters of the prototype (voltage, intensity, application time, power…).

With the contributions received from the consumer area, it was possible to consider consumer preferences in terms of size, materials used, aesthetics or even the price they would be willing to pay for the device.

In summary

The great value of Infinitia, as we have always said, is the people who make it up. Specialized in providing value in the fields of Forensic Engineering, Materials Innovation, and Strategic Design and Prototyping, we are committed to create multidisciplinary teams combining different skills to achieve a better solution. And thus, to face together, the challenges we face.