What was the challenge or problem to solve?

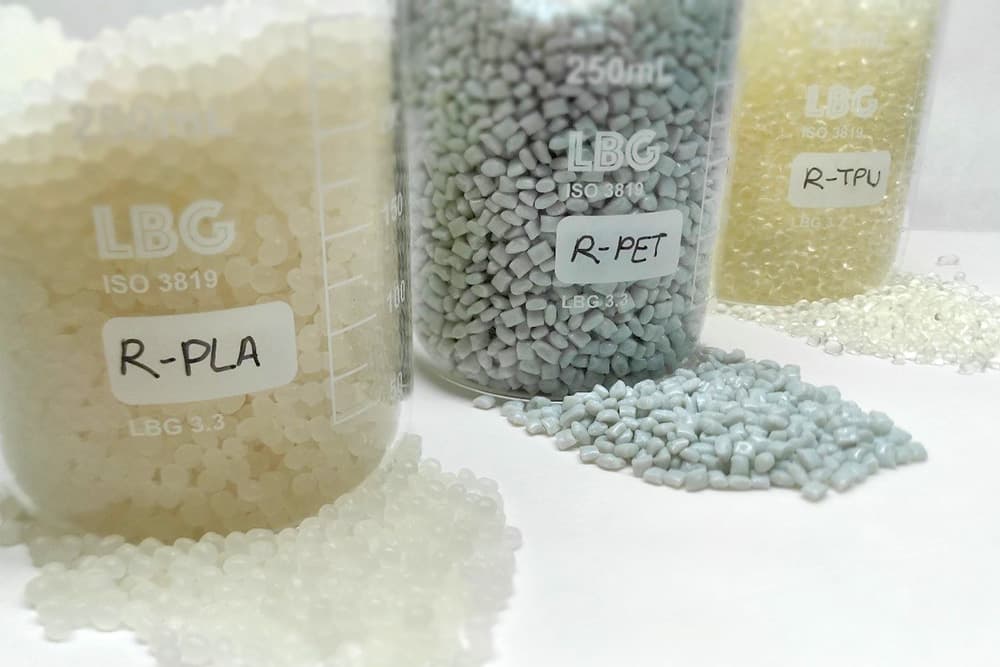

Our client, a company in the industrial sector, was generating a high volume of polymers, such as PLA, PET and TPU, as waste from its manufacturing processes. Faced with this problem, they wanted to determine their potential recyclability, with the aim of giving a second use to this material. To do this, they had to know if it was feasible to recover industrial waste and maintain the appropriate properties of the material.

After carrying out the mechanical characterization of several recycled polymers and comparing the results with the properties of the starting materials, we were able to determine that it was feasible to use these polymers in 3D printing.

We started this project by performing a prospection of the standard for testing. This preliminary phase is essential to establish optimal conditions for mechanical characterization and to design the tests correctly. The dimensions of the specimens to be tested are specified in the prospective standard. Once these data were known, the test specimens were digitized with the indicated geometry. A professional CAD software tool was used for this task.

Since the starting material was in pellet form, it was necessary to wind the polymers. This process made it possible to obtain PLA, PET and TPU filaments, the latter being a format compatible with 3D printers. Then, using these recycled materials and a printer with FDM (Fused Deposition Modeling) technology, the previously designed test specimens were printed.

The next step was the characterization of the specimens. The mechanical properties of the recycled polymers, such as yield strength and Young’s modulus, were obtained by performing tensile tests according to the standard. These tests were carried out on a MUE (universal testing machine).

The analysis of the data obtained made it possible to compare the characteristics of the recycled polymer and the starting polymer. Thus, we were able to establish that the recycled materials had mechanical properties suitable for a second use.

Based on these conclusions, we prepared a final report, in which we indicated to the client the feasibility of giving a second life to the recycled polymers through 3D printing, thus reducing the waste generated and improving the company’s sustainability.