What was the challenge or problem to solve?

The large volumes of metal waste generated during manufacturing processes led one of our industrial customers to assess the feasibility of using it as a new raw material. Thus, the company contacted us and proposed to analyze the waste, which consisted of aluminum shavings, to determine its potential recyclability. In addition, the customer was interested in knowing the characteristics of the material manufactured from this raw material.

With this study, INFINITIA’s Materials Innovation team was able to demonstrate that it was possible to give a second life to this waste and obtain new high quality raw material.

In addition, the reprocessing of the chips achieved another important objective: to reduce the environmental impact of industrial processes and reinforce the company’s commitment to sustainability.

The samples received contained traces of coolant and coolant. Therefore, a cleaning procedure was first designed to remove the residues from the samples. Once prepared, the chips were examined to determine whether their morphological and geometrical characteristics influence the subsequent reprocessing process. A visual analysis with camera and stereo microscope allowed classifying this material according to ISO 3685:1993.

Next, a complete characterization of the chips was carried out in order to define their properties and relate them to the properties of the material obtained from them.

First, an elemental analysis of the residues was carried out to determine the composition of the different chips and to determine which were the majority alloys. Next, colorimetry was carried out to determine the relationship between the type of alloy and its visual appearance. On the other hand, a corrosion study was carried out to determine the degree of resistance of the chips to corrosion.

Another relevant property is the measurement of surface microhardness of the materials, since this test provides information on the mechanical properties of the material, such as strength, ductility or resistance to plastic and elastic deformations.

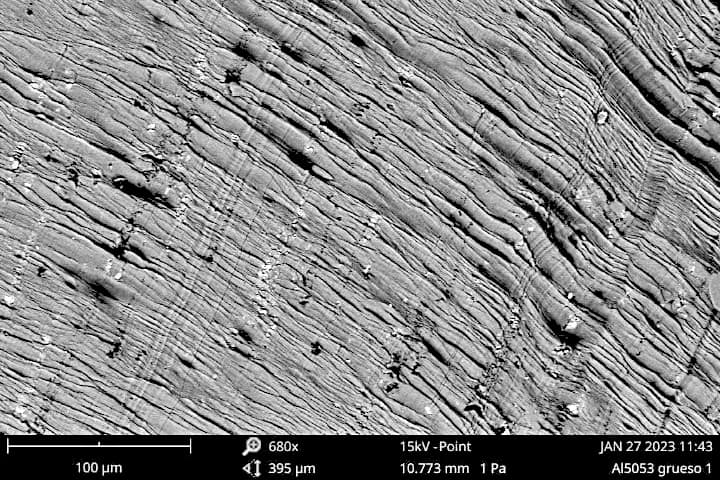

Finally, an examination of the microstructure was carried out to compare possible differences before and after reprocessing. For this study, the samples were metallographed and inspected by scanning electron microscopy.

The analysis of the data obtained gave a positive result. In other words, the material reprocessed from the original waste not only retained properties suitable for a second use, but the new raw material had high quality standards.