What was the challenge or problem to solve?

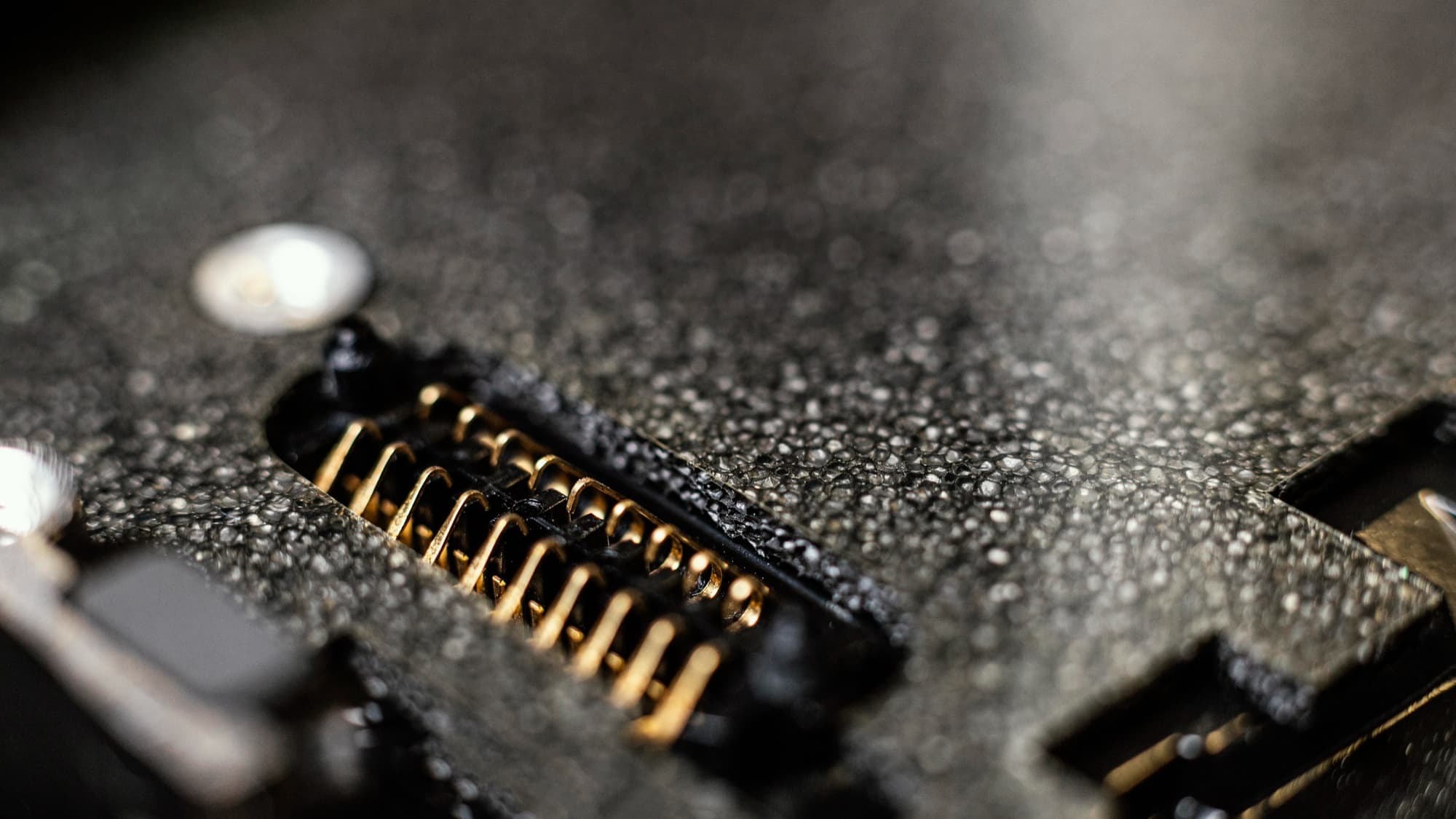

Our client needed specific tools to handle electronic components during their laboratory tests, which presented a significant complication due to the extremely tight tolerances required for the meticulous manipulation of these components.

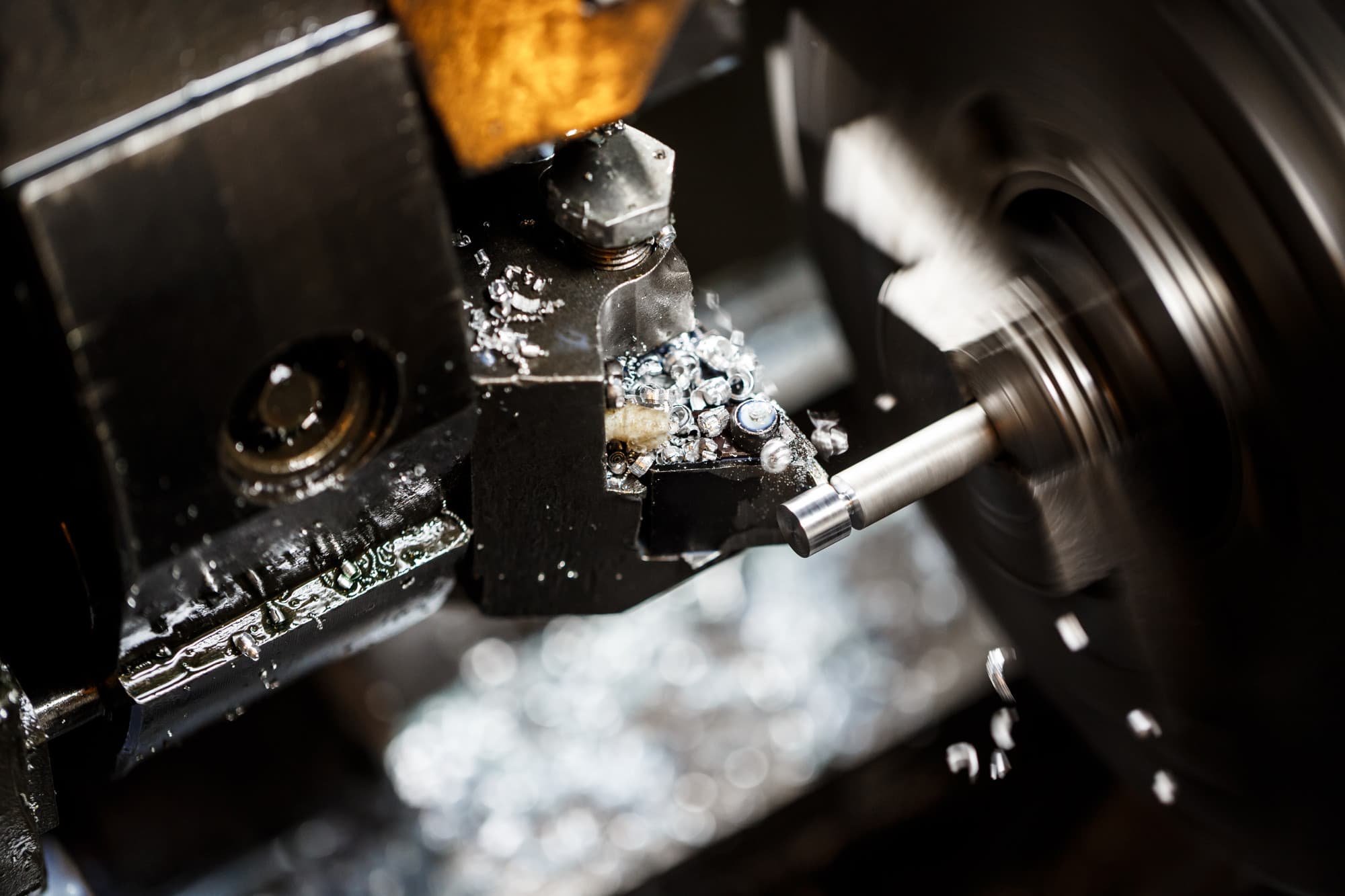

The tools were successfully manufactured and delivered to the client in a very short timeframe, demonstrating INFINITIA‘s effectiveness and efficiency in the redesign and manufacturing of these types of components.

Subsequently, the team proceeded to redesign the tools, adjusting their features to ensure both their manufacturability and improved functionality. This process involved a deep understanding of engineering principles applied to the creation of precision tools.

Finally, detailed technical drawings were created, and contact was made with suppliers to carry out the manufacturing of the tools. Before delivery to the client, a thorough verification was conducted to ensure that the tools met all stipulated requirements, thus guaranteeing client satisfaction and product functionality.