What was the challenge or problem to solve?

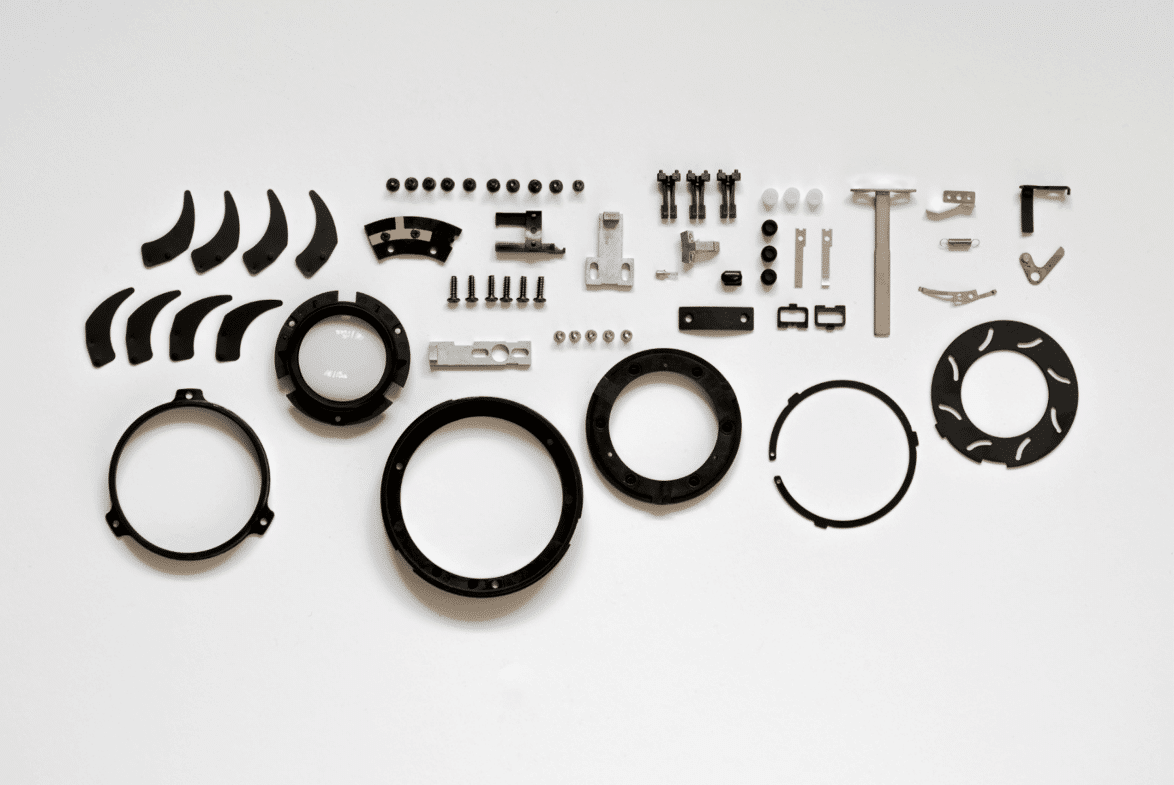

Previously, he had developed an electronic device composed of several assembled plastic elements.

These components had been designed without taking into account the particularities of the plastic part design (wall thicknesses, demolding angles, shrinkage…), so they were not manufacturable and had problems of surface or structural defects.

How was it addressed or what was the solution?

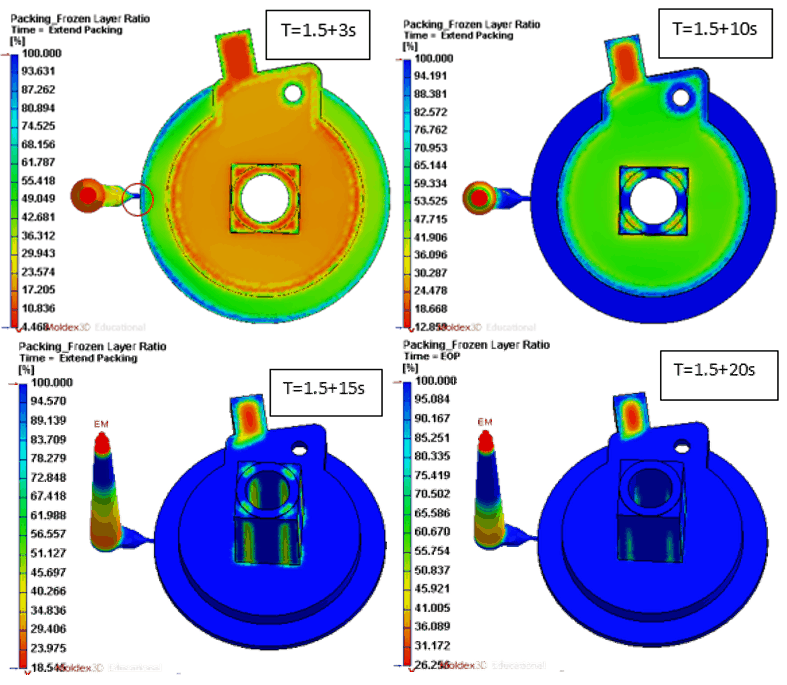

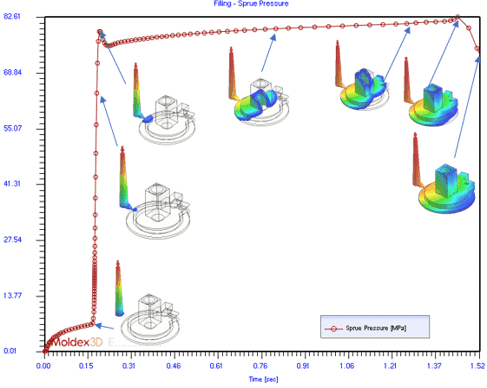

On this occasion, and respecting as much as possible the limitations imposed by the customer, it was decided to carry out design iterations using CAD programs and numerical simulation programs of the injection process.

Finally, the device became an element suitable for manufacturing and industrialization.

Challenge

- Redesign of the product to facilitate its manufacture and industrialization

- Certain particularities of the plastic design had to be maintained, respecting the limitations imposed by the customer

Solution

- Geometric analysis of parts

- Simulation of the plastic injection molding process: identify the most suitable injection point and processing parameters