What was the challenge or problem to solve?

How to deal with the slowdown in the automation of production processes due to a difficulty encountered by the operators of an industrial company? This was the situation detected by one of our client companies and which led them to entrust us with the detection of the different faults that prevented the correct operation of the programme and the search for the most appropriate solution.

Given the complexity of the project, the first internal working sessions were aimed at determining and choosing the most appropriate techniques, optimising the number of analyses and samples. In our experience, this step is essential to perform the identification in an unequivocal way, with quantitative and accurate results.

At a later stage, it was proposed that, in order to solve this situation, it would be very appropriate to carry out an analysis of the systems used by the competition. This type of interaction understanding studies (heuristic bases) are very interesting, as they allow the observation of existing alternatives in the production lines of other companies and help to assess the elements that make them successful.

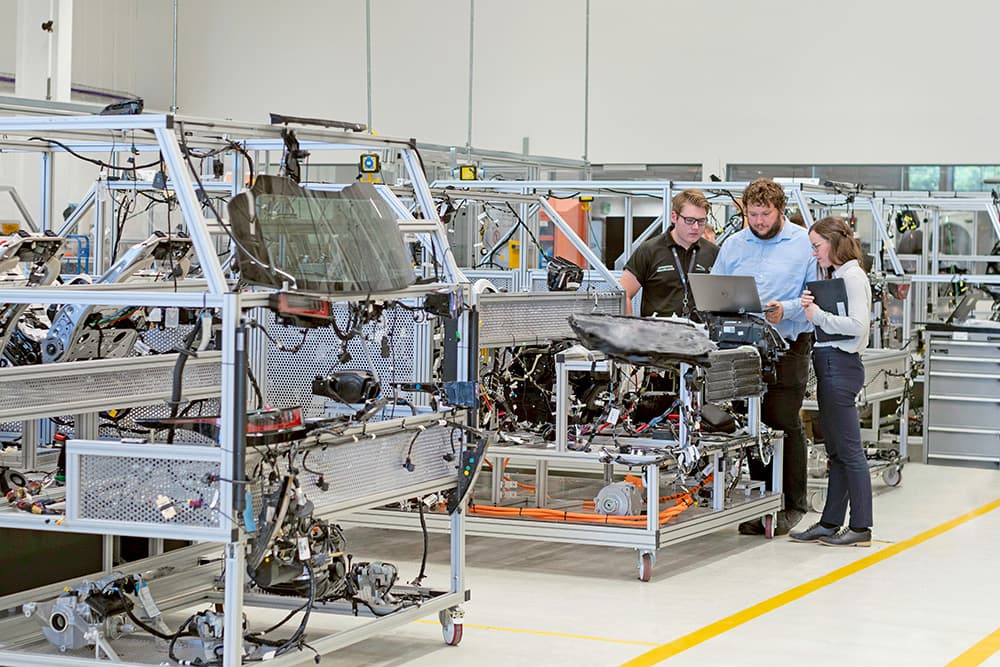

The problem was also considered from the perspective of user analysis. For this purpose, different qualitative techniques were used, such as personal interviews and a focus group with operators working on the production line. The idea was to propose initial wireframes with the different variables contemplated in successful competitor companies and to discuss the possible alternatives that could best meet their needs.

With all the information obtained, INFINITIA’s Strategic Design team developed a redesign of the complete software interface, using different digital product prototyping tools, such as Figma/Adobbe XD. This was carried out by creating a digital prototype, to which the solutions found to the problems detected were added, with the aim of subsequently testing its interaction with the user.

Finally, usability validation was carried out by conducting usability tests with real users on the production line. This direct participation of the users made it possible to evaluate, among many other variables, the time taken to complete a task, errors or the degree of user satisfaction, so that all the established objectives could be achieved in a simple manner.