What was the challenge or problem to be solved?

The INFINITIA team faced the challenge of carrying out a reverse engineering and chemical analysis process for the identification of heavy metals in samples of unknown origin, a key step to define the appropriate way of waste management. The presence of heavy metals can represent a significant risk to health and the environment, so their accurate detection is essential in industrial and waste management contexts.

The main challenge of the project was to carry out chemical analysis of impurities, mainly heavy metals, in samples of unknown origin. This involved the use of advanced techniques that not only identify the metals present, but also provide semi-quantitative contaminant results for each sample. The ability to reliably detect and quantify these elements was key to assessing the potential for recycling and revalorisation, as well as ensuring regulatory compliance in the proper management of the waste.

How was it addressed or what was the solution?

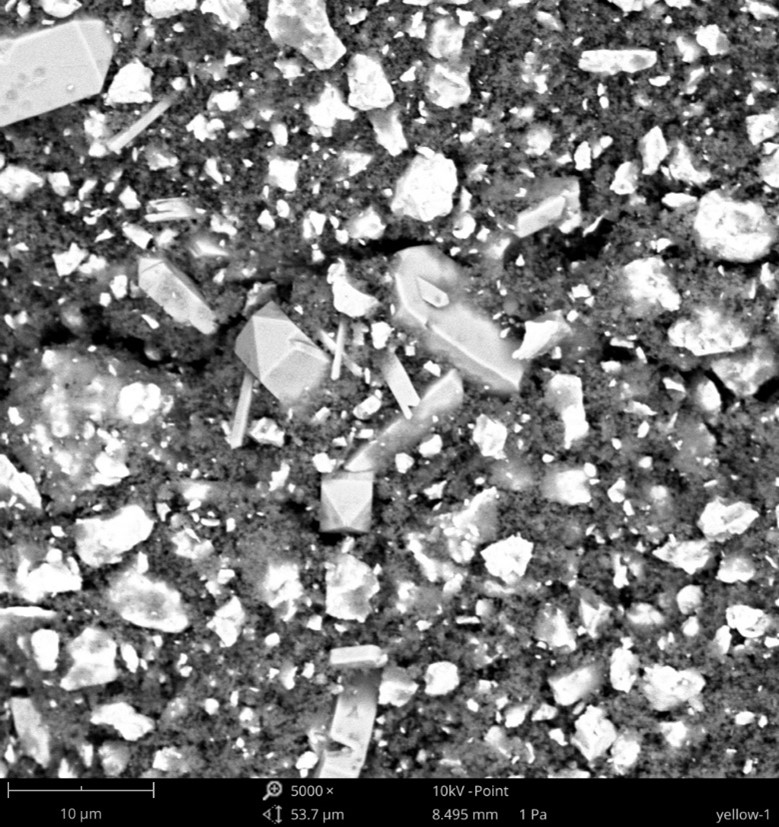

To solve this problem, the INFINITIA team implemented a meticulous process that started with the preparation of the samples. The samples were pre-analysed using an optical microscope to ensure that they were homogeneously distributed. A crucial step in this process was to observe the samples under the microscope to ensure proper sample preparation prior to advanced analysis.

Subsequently, detection and semi-quantification of the heavy metals present in the samples was carried out using scanning electron microscopy coupled to an X-ray detector (SEM/EDX). This technology made it possible to identify the metals and their oxides in a simple and precise manner, providing reliable data on their presence and concentration. The information obtained from the elemental chemical analysis by SEM/EDX allowed informed decisions to be made on the appropriate treatment of the analysed materials.

The success of the project was evidenced by the accurate identification and semi-quantification of heavy metals in all samples analysed, providing the client with detailed information to make strategic waste management decisions. This approach provided the client with clear and reliable information that enabled them to manage waste appropriately, ensuring regulatory compliance and minimising potential environmental and health risks.