What was the challenge or problem to solve?

Our Product Development team was in charge of this interesting case, centred on the adaptation of the design of a support for a machine vision camera to be placed on a robotic arm. This redesign was approached taking into account that the part was to be manufactured using 3D printing.

According to what the client informed us, he had received a file with the design in .stl format intended for 3Dprinting and, therefore, not editable. Once printed, the customer found that the part had very poor structural integrity. In addition, due to the need for supports for its manufacture, it generated a considerable amount of waste material.

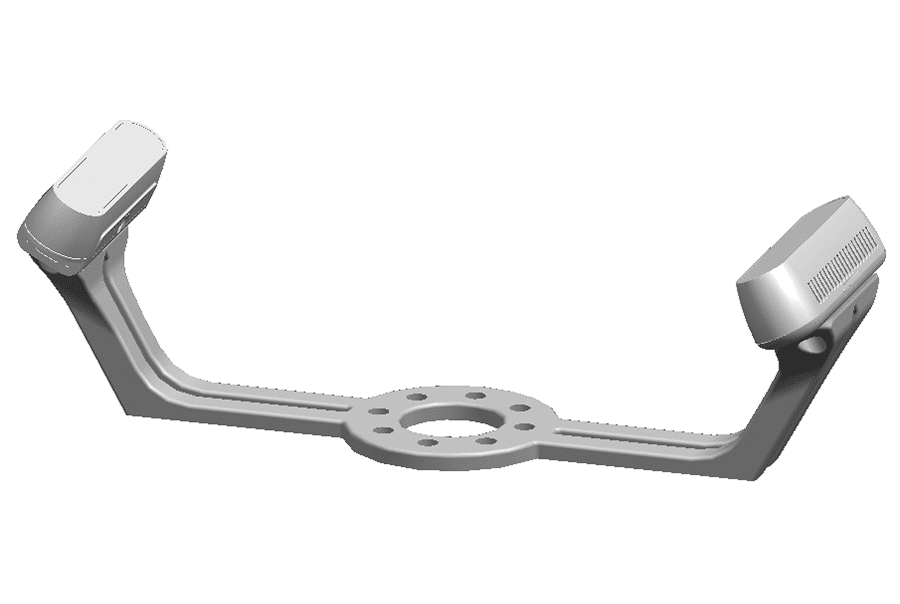

Faced with this situation, the client contacted us to perfect the design of the bracket. The new development had to meet several requirements: maintain the geometric restrictions of the original positioning of the cameras with respect to the robotic arm, achieve a robust, resistant and as light as possible part and, finally, avoid the use of brackets for its manufacture.

Thanks to a thorough process of reverse engineering, mechanical development and validation, we were able to create a design that met all of our client’s requirements and could be printed without the need for extra material.

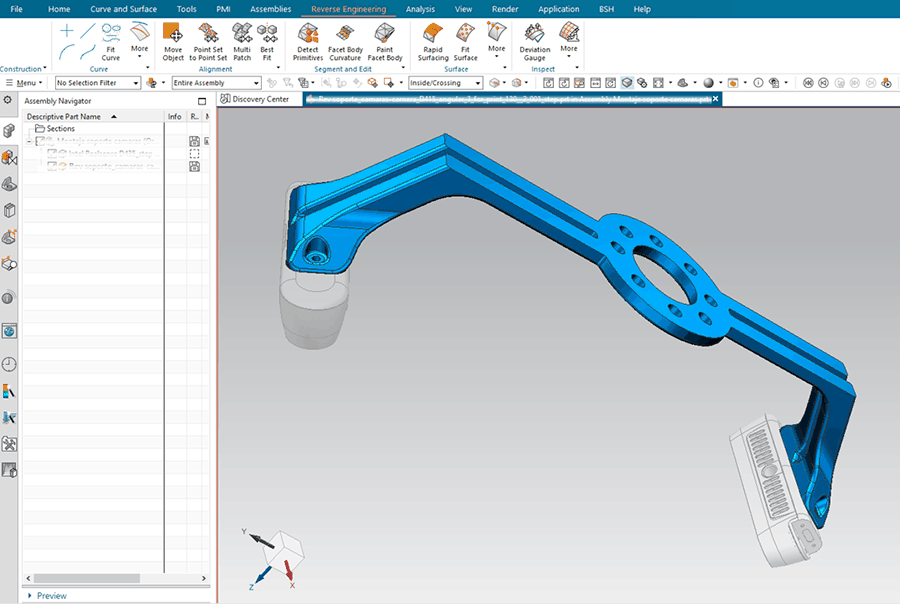

Since the starting point was a non-editable .stl file, a solid had to be obtained from it. This material would allow us to work within the 3D modelling software and maintain the original geometric constraints of the model with the position of the cameras with respect to the robotic arm. We therefore studied the requirements carefully and reverse-engineered the original file using professional 3D modelling software.

This important preliminary work was followed by the adaptation and mechanical development of the part. The use of professional digital tools and our team’s know-how about mechanical design and 3D printing were key elements to ensure a robust and efficient design, reduce the amount of material used in its manufacture and minimise waste generation.

The part was manufactured from the new design using a fused wire 3D printer (FDM). This precision technology is capable of producing large parts in technical materials. It is also fast and cost-effective, enabling an optimum design to be achieved in the shortest possible time and with the lowest possible investment.

The last phase consisted of on-site assembly and testing of the new design at the customer’s premises. In this way, it was possible to verify its validity during the actual use of the robotic arm, to ensure that the result corresponded 100% with the customer’s needs and to speed up possible modifications, if necessary.