What was the challenge or problem to solve?

The Forensic Engineering team at INFINITIA faced a problem that a Waste Treatment Plant was experiencing. The facility was encountering recurring failures in its machinery, specifically in the obstruction of a crucial filter for its operation. This issue, which compromised the efficiency of waste treatment, required an urgent and effective solution.

This challenge was particularly complex due to the unknown nature of a material causing an obstruction. The plant had identified a substance that was interfering with the filter’s function, but the composition of this substance was uncertain.

INFINITIA’s mission was to resolve the incident through a thorough analysis that could identify the composition of the material responsible for the failure.

The main objective of the project was to clarify the exact cause of the problem, focusing on identifying the components of the sample, with special attention to those of plant origin, which were suspected to be the main cause of the obstruction. The ultimate goal was to provide the client with a solid basis for implementing solutions that would prevent future operational problems at the plant.

To tackle this challenge, the Forensic Engineering team began with the manual separation of the sample in a controlled laboratory environment. This first phase was crucial to adequately prepare the sample for further analysis, ensuring that all necessary conditions for a detailed study were present.

The next step involved an initial visual analysis using a binocular magnifying glass. This equipment allowed the experts to observe the sample with greater detail than the naked eye, facilitating the preliminary identification of the various components present. This visual analysis was fundamental to guide the later stages of the study towards the most relevant elements of the sample.

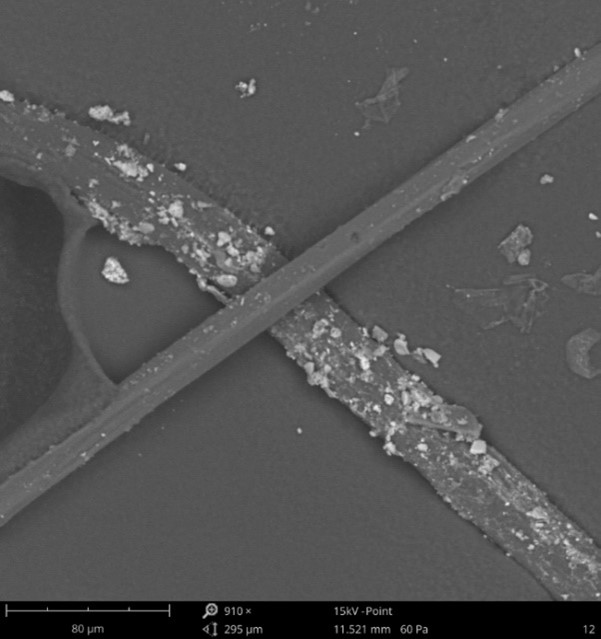

Subsequently, a more detailed analysis and characterization of the materials were conducted using a Scanning Electron Microscope (SEM). The SEM provided high-resolution images and allowed for chemical composition analysis, essential for identifying and characterizing the components of the sample in detail. Thanks to this advanced technology, the team was able to confirm the nature of those responsible for the obstruction of the filter in the plant’s machinery.

This approach not only allowed for the precise identification of the cause of the problem but also provided an effective solution to the client. By clarifying the composition of the sample, INFINITIA was able to offer specific recommendations to avoid future obstructions, thus improving the efficiency and operability of the urban waste treatment plant.