What was the challenge or problem to solve?

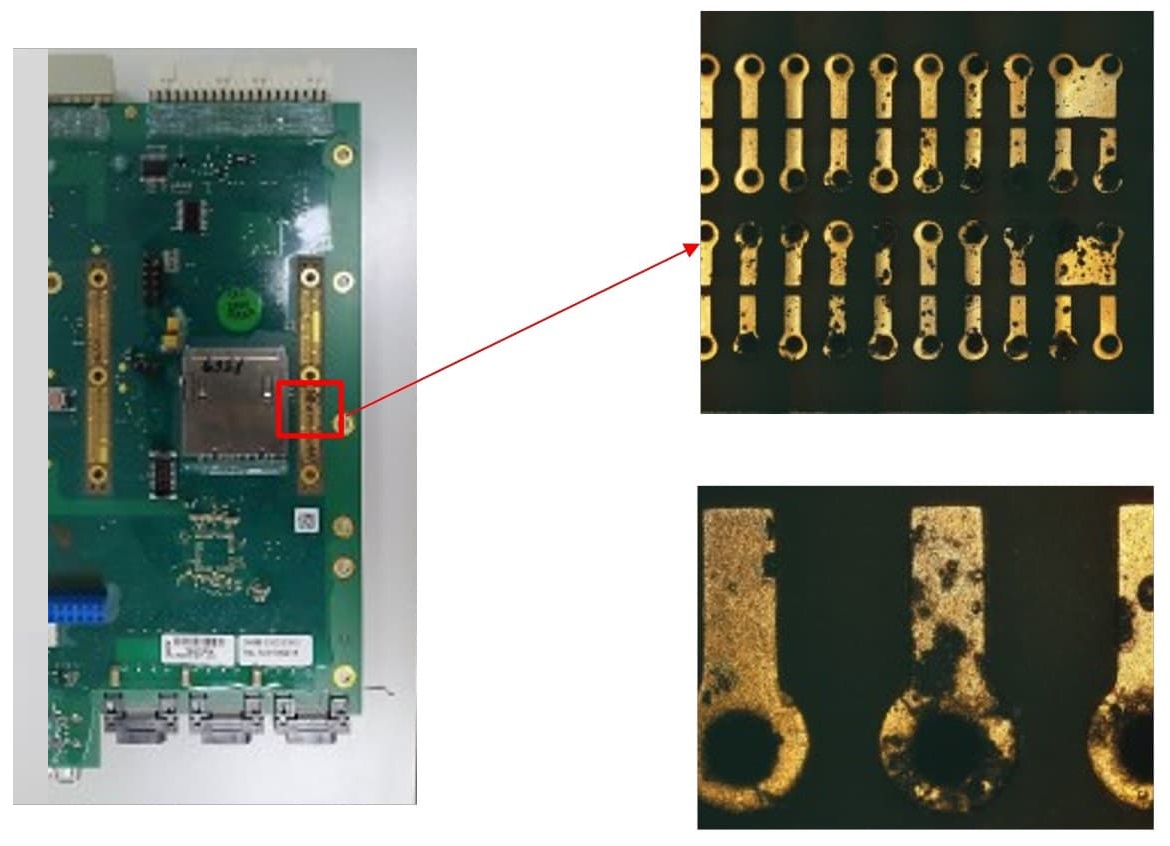

A client contacted INFINITIA because they were facing an issue with defective electronic boards that had been withdrawn from the market due to operational failures. These boards exhibited unknown residues, and there was a need to understand their chemical composition, their origin, and thereby establish responsibilities or prevent future incidents.

The project was approached through a rigorous selection of analytical techniques. The analytical process began with a detailed inspection using optical microscopy to locate the areas affected by the residues.

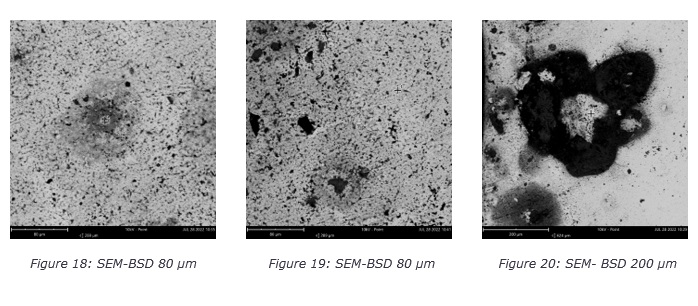

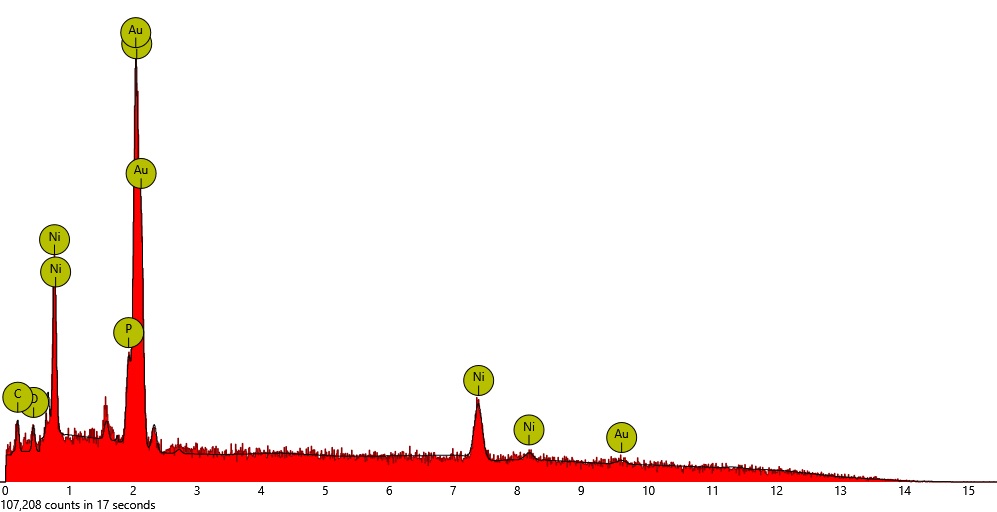

To understand the morphology of the residues in detail, SEM (Scanning Electron Microscopy) examination was conducted, and their chemical composition was determined through EDX (Energy Dispersive X-ray Analysis), thus providing a detailed profile of the detected residues.

Finally, with all the information gathered, it was concluded that the residues were not caused by circuit corrosion, but were deposits generated by external environments. The accumulation of these residues on the metal surface could severely influence the surface’s conductivity, and therefore affect the functionality of the board.

The investigation carried out by INFINITIA enabled the client to precisely identify the underlying problem and implement corrective measures in production, thus ensuring the quality and reliability of future products.