What was the challenge or problem to solve?

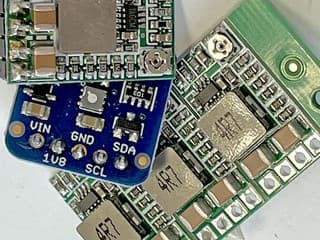

In this project we carried out a forensic engineering investigation focused on checking and authenticating electronic components, or on the contrary, detecting counterfeits. When carrying out tests on their PCBs, the client had detected some failures, which led them to think that some of the elements used did not comply with the specifications in their technical data sheet and, therefore, could be fraudulent.

Once the protocols of the procedure to be followed had been established, we were able to verify the base and the interior elements of the components, determining whether there had been a forgery or a manufacturing defect in the parts.

The Materials Innovation team began by carrying out a bibliographic search of the existing information on the approved standards for authentication of the elements to be analysed. After studying the documentation found, an action protocol was designed with the most appropriate techniques for this process..

First, a series of tests were carried out using non-destructive techniques, starting with the least invasive analysis techniques. This allowed us to keep the samples as intact as possible before using more aggressive means.

Once this stage was completed, we proceeded to develop more destructive tests that allowed us to get inside the component. This allowed us to check in detail its base, its interior elements, and its chemical composition, establishing if there were any manufacturing faults and if the elements complied with the indications established by the manufacturer.