What was the challenge or problem to solve?

One of our clients observed the formation of cracks in their plastic parts, raising serious concerns about the integrity of the material used in their manufacturing.

Faced with the possibility that these defects were due to an unfavourable proportion of raw material components, it became necessary to conduct a technical study to validate the composition and thermal properties of the polymer.

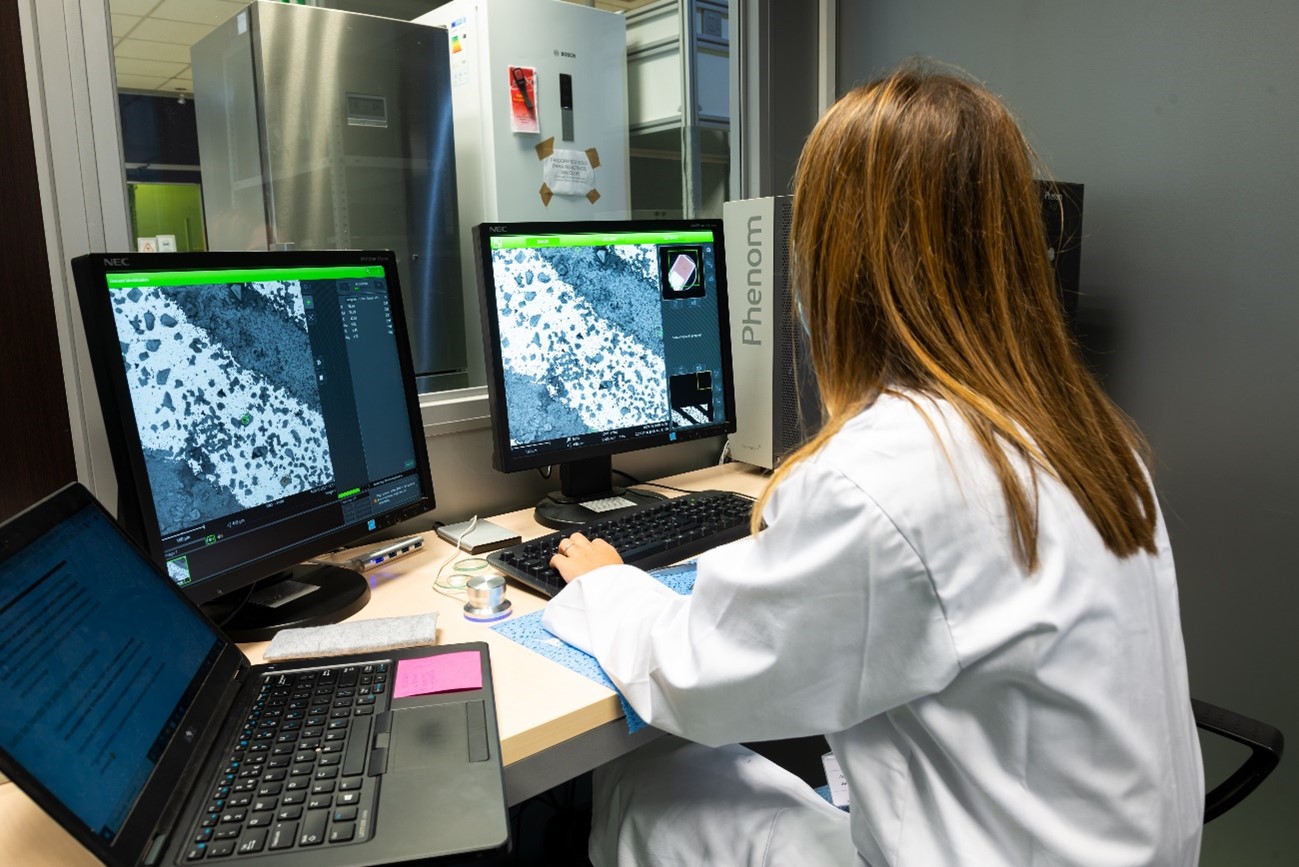

To tackle this challenge, the Forensic Engineering team began by conducting a detailed analysis of the material composition, using composition analysis techniques to identify possible additives, contaminants, and the degradation state of the polymer. This step was crucial to rule out the presence of unwanted elements that could compromise the material’s integrity.

Subsequently, a Thermogravimetric Analysis was performed to obtain precise information about the composition, including inorganic fillers and impurities, as well as to assess the thermal stability of the material. This analysis provided information on how the material responded to different temperatures, a critical factor in preventing premature degradation.

Additionally, the thermal properties of the material were studied to better understand its behavior under normal and extreme usage conditions. This study allowed the team to determine whether differences in thermal behavior could be behind the crack formation.

The interpretation of the results, complemented by an exhaustive literature review, enabled the team to confirm the various hypotheses put forward, allowing the client to identify the cause of the failure and take the necessary corrective measures in production.