What was the challenge or problem to solve?

The challenge faced by the Materials Innovation team at INFINITIA was to evaluate the corrosion behaviour exhibited by assemblies that a client was working on.

This study was motivated by the client’s need to improve the appearance and functionality of their product by incorporating an additional component made from a material different from the rest of the product.

To meet this challenge, the project was developed in several key stages. Initially, a visual inspection of the samples was conducted to ensure they were in optimal condition for the study, eliminating any variable that could distort the results in the tests.

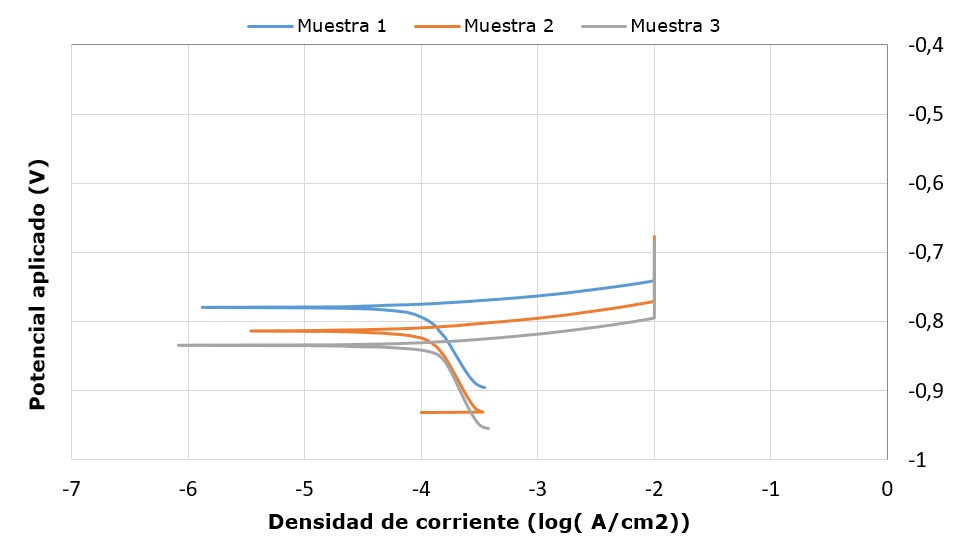

Subsequently, the evaluation of corrosion resistance was performed using advanced electrochemical techniques, utilizing a potentiostat in accordance with the ISO 17475:2005 standard. This approach allowed for the detection of corrosion presence and also the prediction of its onset, offering a quantitative and qualitative understanding superior to traditional methods.

The design of the test setup was a critical component of the project, as the unique geometry of the parts demanded a custom solution. This customization ensured that tests could be conducted precisely and reproducibly.

Finally, the analysis of the results allowed for the estimation of the corrosion rate, and therefore the expected durability, thereby comparing the resistance among the assemblies proposed by the client.

This approach resulted in the selection of the most suitable assembly for the final application of the product, successfully avoiding potential future problems by scientifically and conclusively demonstrating which assemblies are the most suitable.