What was the challenge or problem to be solved?

A client wanted to certify and confirm that a material supplied by a new steel supplier with more competitive costs could be used safely in a high-temperature application without generating harmful emissions.

They wanted to ensure compliance with the REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation (certain compounds are restricted), as well as paying special attention to certain volatile substances as certain volatile organic compounds (VOCs) can have harmful effects on health.

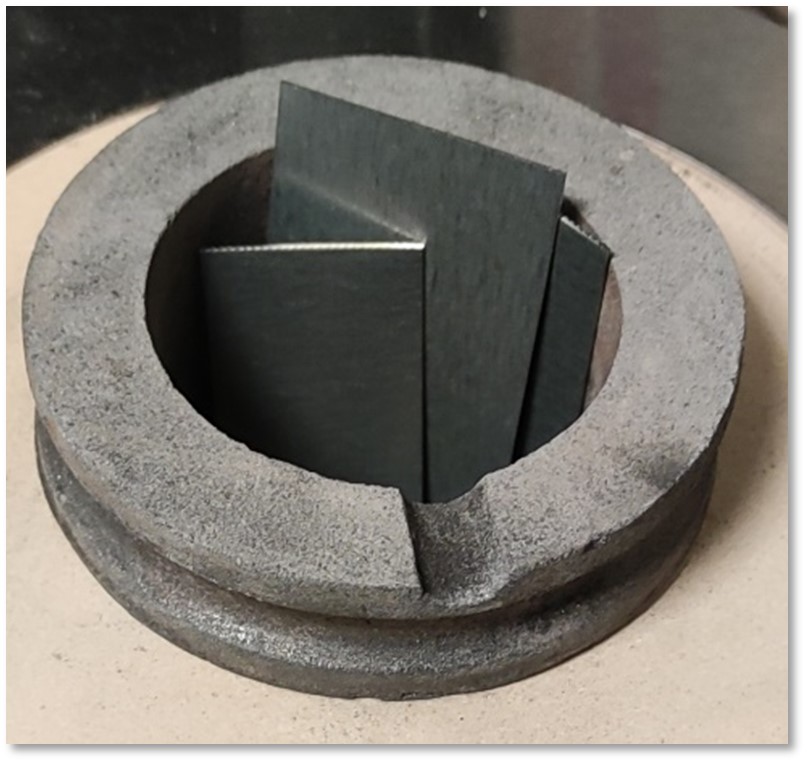

The main challenge of this project, which INFINITIA took on, was to design and validate a customised analysis method to analyse the emissions generated at high temperatures. There was no equipment or pre-established, standardised methodology that would allow us to work at the range of temperatures required by the client.

How was it addressed or what was the solution?

To do this, an oven was designed and improved that allowed work to be carried out at high temperatures, and the capture of emissions in an effective, efficient and reproducible way. This innovative approach made it possible to work with very small quantities of steel without compromising the accuracy of the analysis.

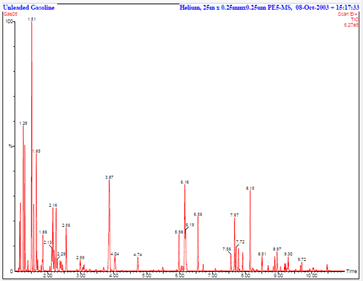

Subsequently, the captured emissions were analysed by thermal desorption coupled with gas chromatography and mass spectrometry (GC-MS). This technique made it possible to reliably identify and quantify the volatile organic compounds present in the samples. Thanks to this advanced chemical analysis, a detailed profile of the emissions generated was obtained.

Finally, the results were compared with health reference values, such as the TLV-TWA and TLV-STEL, to assess potential emission risks.

This analysis concluded that the emissions generated by steel at high temperatures did not represent a health risk, which gave the client the necessary assurance to approve this new supplier and optimise costs in the production process.

The project was a success as it fulfilled two key objectives: the development of a robust method for analysing VOCs at high temperatures and the approval of a new material that allowed the client to optimise costs.

This work demonstrates INFINITIA’s ability to solve complex technical problems, offering customised solutions that guarantee the quality and safety of our clients’ products and optimise costs in the production chain.