What was the challenge or problem to solve?

The electronics, automotive and aerospace industries face the constant challenge of guaranteeing the durability and reliability of their components under extreme conditions through the homologation of materials. One of the most demanding challenges for these sectors is the resistance of their technologies to sudden temperature changes, capable of causing critical failures in the systems.

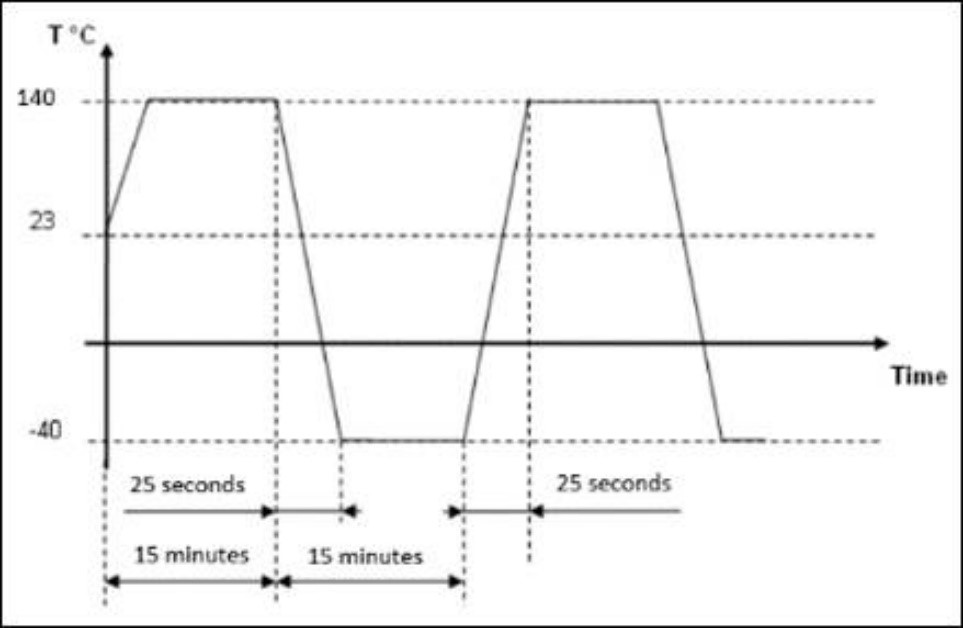

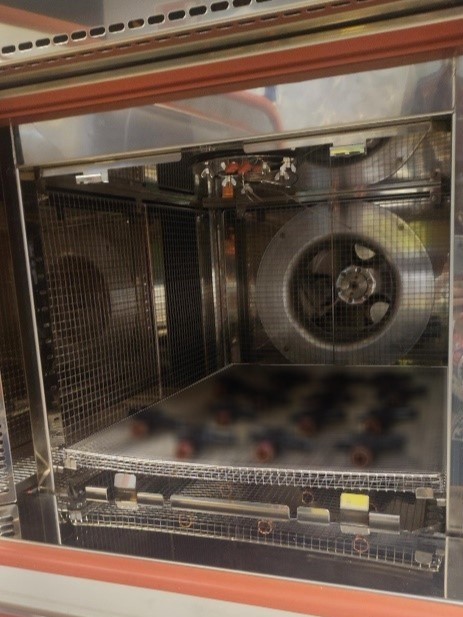

The Forensic Engineering team followed a structured methodology to address this challenge. The first step was to conduct thermal shock tests using an advanced test chamber capable of rapidly oscillating between very high and very low temperatures. This procedure simulated the harsh conditions to which the components can be exposed, evaluating their reaction to the rapid expansion and contraction caused by thermal changes.

This was followed by visual and microscopic analysis to identify potential surface damage, such as cracks, deformations or colour alterations. This phase was crucial to detect the immediate effects of thermal stress on the materials.

The final phase included mechanical testing to verify whether the mechanical properties of the components were affected after undergoing these extreme tests.

This approach provided remarkable benefits, offering essential data on component durability and reliability. As a result, stronger and safer designs have been developed, providing effective solutions to complex technical challenges.